Home

>

Airgun Rendezvous Main Forum

>

Topic

Edge Testing - Shaving Chips of Cold Rolled Steel!!!

Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 08, 2020 01:04AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

This is always a great test. If a heat treated blade can do this, it’s a good blade.

Cold Rolled Steel is harder than Hot Rolled. The forming process “Work Hardens” the material. I use a smallish rod of Cold Rolled, probably 5/16” diameter. The fact that I’m going to cut steel is now made much worse. The circumference means that now the blade is only touching the steel at one point! That focuses the force on a tiny point of edge.

I press, let the blade edge bite, and shave forward. At the end, the edge resurfaces and pops the chip off. Try it. If the blade is too soft, the edge will bend and mold to the rod. If the edge is too hard, the steel will chip out. (Probably won’t ruin your blade but it will require you remove metal to make a clean edge again.

Now the edge geometry must be designed to be tough enough. If you forced a very fine slicing blade and were not steady, you might damage even a good blade. But my knife ... “I named him Mac”, is pretty thin and fine. Take a look ...

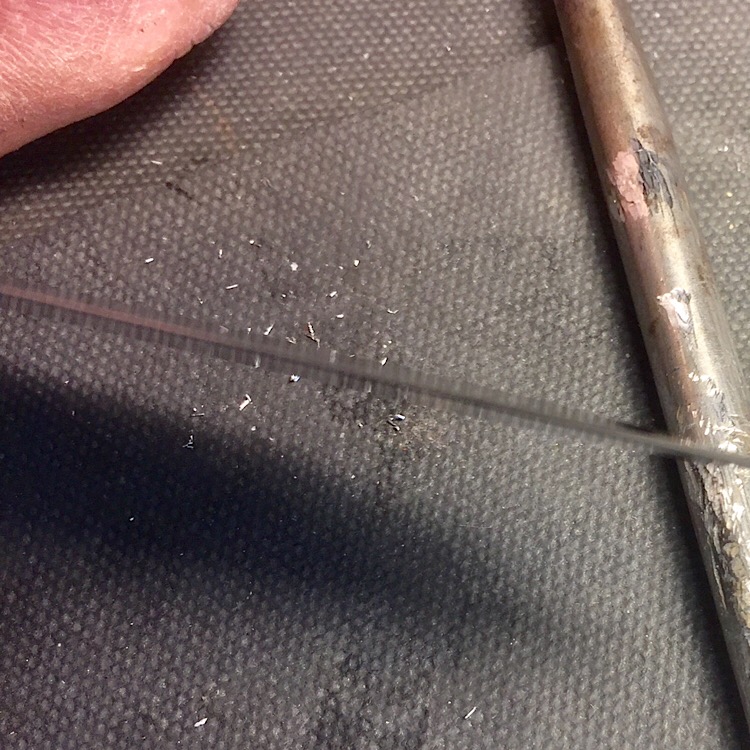

Note the Rod and Steel Chips.

I did it here and there, but really concentrated on this center 3/4” section.

Looking down on the edge. See it? No??? Good. Me either. A flat spot or chip would reflect light!

Thanks

Dinner!!!!!

Gary

Cold Rolled Steel is harder than Hot Rolled. The forming process “Work Hardens” the material. I use a smallish rod of Cold Rolled, probably 5/16” diameter. The fact that I’m going to cut steel is now made much worse. The circumference means that now the blade is only touching the steel at one point! That focuses the force on a tiny point of edge.

I press, let the blade edge bite, and shave forward. At the end, the edge resurfaces and pops the chip off. Try it. If the blade is too soft, the edge will bend and mold to the rod. If the edge is too hard, the steel will chip out. (Probably won’t ruin your blade but it will require you remove metal to make a clean edge again.

Now the edge geometry must be designed to be tough enough. If you forced a very fine slicing blade and were not steady, you might damage even a good blade. But my knife ... “I named him Mac”, is pretty thin and fine. Take a look ...

Note the Rod and Steel Chips.

I did it here and there, but really concentrated on this center 3/4” section.

Looking down on the edge. See it? No??? Good. Me either. A flat spot or chip would reflect light!

Thanks

Dinner!!!!!

Gary

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 08, 2020 06:06PM |

Admin Registered: 15 years ago Posts: 1,489 |

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 09, 2020 03:55PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Lon,

I go by experience and imperial testing like described and documented above.

I couldn’t tell you the degrees of angle. The intended use will determine that for me, and my muscle memory will dial in that setting to hand hold the steel to wheel.

I don’t Rockwell test. You need a flat parallel top and bottom to Rockwell test. The diamond point can’t be applied to a wedge shaped edge. And I differentially heat treat everything. So testing the flat spine only shows you the spine spring hardness. Again, the edge geometry will determine how a given hardness will hold up. If you’d give me your 17 degree 61 Rockwell C Scale blade from somebody’s article, I guarantee I could chip the edge. It’s how the edge is shaped and how it’s used. I’m sure someone else could make a mess out of my blade above too. I’m demonstrating that with proper technique, proper heat treating, and proper edge geometry; my blade can withstand EVEN mild abuse. Not that it’s a stand-in for bolt cutters, etc. But it has been very well made.

This blade is A2 Lon. I like it for my standard blades. It’s a very good Air Hardening Tool Steel. It’s also rust resistant. Now, if you carry it in your sweaty jeans pocket while you work hard day after day, you’ll get spots on it. But then, it’s a work knife and a pocket friend.

I also like O-1 Tool Steel. That is not stainless at all. It’s a fine Oil Hardening Tool Steel. Keep it in a drawer, and it will stay bright.

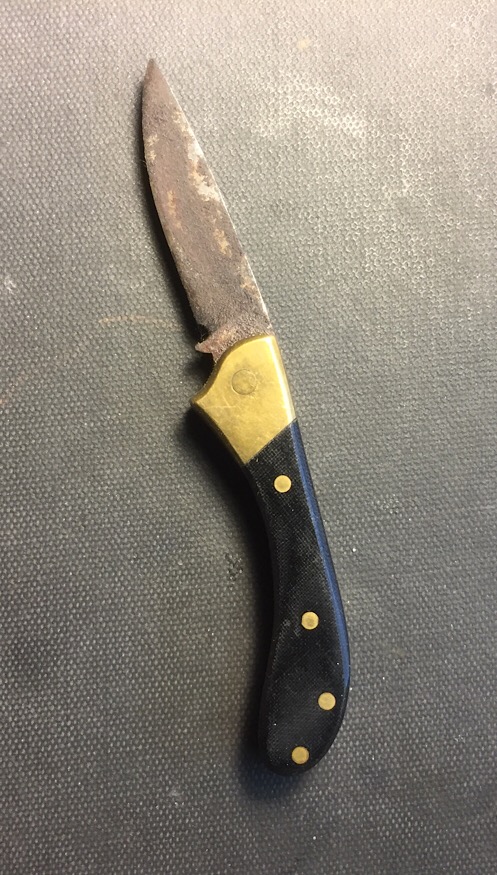

Keep it on a wooden shelf, above a shower, in the basement of a farmhouse; and it will look like this one. Made for my Dad. Probably in the first dozen or so I ever made.

Thanks Lon. Just giving my way of establishing my knives, to last several lifetimes of use.

Best my Friend,

Gary

Edited 1 time(s). Last edit at 05/09/2020 04:03PM by barnespneumatic.

I go by experience and imperial testing like described and documented above.

I couldn’t tell you the degrees of angle. The intended use will determine that for me, and my muscle memory will dial in that setting to hand hold the steel to wheel.

I don’t Rockwell test. You need a flat parallel top and bottom to Rockwell test. The diamond point can’t be applied to a wedge shaped edge. And I differentially heat treat everything. So testing the flat spine only shows you the spine spring hardness. Again, the edge geometry will determine how a given hardness will hold up. If you’d give me your 17 degree 61 Rockwell C Scale blade from somebody’s article, I guarantee I could chip the edge. It’s how the edge is shaped and how it’s used. I’m sure someone else could make a mess out of my blade above too. I’m demonstrating that with proper technique, proper heat treating, and proper edge geometry; my blade can withstand EVEN mild abuse. Not that it’s a stand-in for bolt cutters, etc. But it has been very well made.

This blade is A2 Lon. I like it for my standard blades. It’s a very good Air Hardening Tool Steel. It’s also rust resistant. Now, if you carry it in your sweaty jeans pocket while you work hard day after day, you’ll get spots on it. But then, it’s a work knife and a pocket friend.

I also like O-1 Tool Steel. That is not stainless at all. It’s a fine Oil Hardening Tool Steel. Keep it in a drawer, and it will stay bright.

Keep it on a wooden shelf, above a shower, in the basement of a farmhouse; and it will look like this one. Made for my Dad. Probably in the first dozen or so I ever made.

Thanks Lon. Just giving my way of establishing my knives, to last several lifetimes of use.

Best my Friend,

Gary

Edited 1 time(s). Last edit at 05/09/2020 04:03PM by barnespneumatic.

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 08, 2020 10:43PM |

Registered: 15 years ago Posts: 234 |

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 09, 2020 03:20PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I’ve been considering making some kitchen knives Rick. This jig might be key to that.

Karl asked me for one years back. Then my brain hadn’t yet reminded me when life hadn’t yet gotten dibs on me. I’m getting there.

Oddest stuff interferes as everywhere. I walk into the grinding room yesterday, to find gloom and dimness. A fixture over my grinders was out. That promoted the game of changing tubes. Is it tubes or the ballast? New fixtures are so cheaply made that you just have to toss them. I have a stack of questionable ones in a corner. Put one new tube in a questionable fixture for a replacement, and I got a blinding flash and the tube went dark. Probably ruined that one. Little stuff that eats up hours. I never did get it corrected to get light inside before it got dark outside. But I did vacuum half a ton of dust off of stuff. I need better dust recovery, and time to establish a hose and tube network.

Ok. Kitchen knife by candlelight! Coming up Rick.

For those wondering, the Pistols haven’t been abandoned. Just moved back an inch to lay down a couple knife parts and Mrs. Kelly’s Mother’s Day gift.

Health has been a mixed bag. We are dealing with it. You note how something which wasn’t your doing, can come in and just change everything about your life? Yes, me too. I’ve been coping for a long time now.

God Bless you all, stay safe.

Gary

Edited 1 time(s). Last edit at 05/09/2020 04:10PM by barnespneumatic.

Karl asked me for one years back. Then my brain hadn’t yet reminded me when life hadn’t yet gotten dibs on me. I’m getting there.

Oddest stuff interferes as everywhere. I walk into the grinding room yesterday, to find gloom and dimness. A fixture over my grinders was out. That promoted the game of changing tubes. Is it tubes or the ballast? New fixtures are so cheaply made that you just have to toss them. I have a stack of questionable ones in a corner. Put one new tube in a questionable fixture for a replacement, and I got a blinding flash and the tube went dark. Probably ruined that one. Little stuff that eats up hours. I never did get it corrected to get light inside before it got dark outside. But I did vacuum half a ton of dust off of stuff. I need better dust recovery, and time to establish a hose and tube network.

Ok. Kitchen knife by candlelight! Coming up Rick.

For those wondering, the Pistols haven’t been abandoned. Just moved back an inch to lay down a couple knife parts and Mrs. Kelly’s Mother’s Day gift.

Health has been a mixed bag. We are dealing with it. You note how something which wasn’t your doing, can come in and just change everything about your life? Yes, me too. I’ve been coping for a long time now.

God Bless you all, stay safe.

Gary

Edited 1 time(s). Last edit at 05/09/2020 04:10PM by barnespneumatic.

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 12, 2020 01:42PM |

Registered: 12 years ago Posts: 2,189 |

Gary

I’ve always loved this test . I REALLY appreciate the you tube video of you shaving a metal rod too since I’m a skeptic always .

You can definitely put me down for the kitchen knife series along with Karl . I’m always looking for a great chef knife. There’s a new commercial on tv (infomercial) offering a nice looking Damascus blade chef knife. Hmmm

I really enjoy seeing the knife you made for you father too . I’m sure he didn’t want to use it for a carry knife due to sentimental value .

Ok on to fluorescent tube lights . A couple years ago maybe 2 I switched my garage lights to all the round screw in bulb LED light 100 watt . Man Im so happy . I don’t have heat in the

garage so in the coldest day of winter they take a minute to warm up but they are bright .Of course there’s different types you can get to your liking but they are great in my opinion!

I’ve never had one go bad and even in my drop light I don’t need rough service bulbs . They’re tuff as a Waffle House steak. Maybe the name drop light says it all ! Haha

Those 100 watt are so bright you can’t look at them and I’m sure they go bigger too . Ya just hafta find a good shade and throw / cast to fit your shop !

Btw the price has come down and quality gone up I’m my opinion too .

Take care and stay healthy my friend.

Thanks

Kurt

I’ve always loved this test . I REALLY appreciate the you tube video of you shaving a metal rod too since I’m a skeptic always .

You can definitely put me down for the kitchen knife series along with Karl . I’m always looking for a great chef knife. There’s a new commercial on tv (infomercial) offering a nice looking Damascus blade chef knife. Hmmm

I really enjoy seeing the knife you made for you father too . I’m sure he didn’t want to use it for a carry knife due to sentimental value .

Ok on to fluorescent tube lights . A couple years ago maybe 2 I switched my garage lights to all the round screw in bulb LED light 100 watt . Man Im so happy . I don’t have heat in the

garage so in the coldest day of winter they take a minute to warm up but they are bright .Of course there’s different types you can get to your liking but they are great in my opinion!

I’ve never had one go bad and even in my drop light I don’t need rough service bulbs . They’re tuff as a Waffle House steak. Maybe the name drop light says it all ! Haha

Those 100 watt are so bright you can’t look at them and I’m sure they go bigger too . Ya just hafta find a good shade and throw / cast to fit your shop !

Btw the price has come down and quality gone up I’m my opinion too .

Take care and stay healthy my friend.

Thanks

Kurt

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 13, 2020 02:35PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Great Post Kurt,

Tough as a Waffle House Steak! Hahahaaah. I love that! Thanks for the saying and the tip.

I’m a fan of the LED too. Walmart has some 18”ish tube LED lights. $9 and change. One of them will light half a shop! Amazing. Yeah, the last gasp of florescent fixtures was a disappointment. The tubes will last longer than the fixtures. The pull switches lock up after a few months or less. Now they do make LED tube replacements now! But your fixture has to work. I have a stack of bad units like firewood. Waiting to go to the crusher.

I’m anxious to get back to the Pistols. Anxious to get a few Pack knives out too. Three things have slowed progress. 1). Ouch!!!! 2). A few things that just had to be done here about. 3). I had a repeatability issue with my grinding rig. There are several built in adjusts. Those were good. But there was a gremlin I couldn’t find. An intermittent thing (which are THE worst kind). I think I found it this am. A line of milling burr I missed cleaning off the base metal, down inside the clamping head. “Sometimes”, the burr ledge would catch and it seemed like the unit was seated. In reality, it was short sheeting the seating juuuuust a bit. This thing is precise and screw ups can result from misalignment.

This isn’t like you clamp a bar of steel in and come back an hour later to a bucket of shiny blades. I massage the blade done, and it has to come out for heat treating and for the other side, then go back in precisely afterwards to finish. It’s that repeat factor that separates the quality tools from the hammers.

Got to get back and change the bucket! Haha.

Thanks Kurt

Blessings

Gary

Tough as a Waffle House Steak! Hahahaaah. I love that! Thanks for the saying and the tip.

I’m a fan of the LED too. Walmart has some 18”ish tube LED lights. $9 and change. One of them will light half a shop! Amazing. Yeah, the last gasp of florescent fixtures was a disappointment. The tubes will last longer than the fixtures. The pull switches lock up after a few months or less. Now they do make LED tube replacements now! But your fixture has to work. I have a stack of bad units like firewood. Waiting to go to the crusher.

I’m anxious to get back to the Pistols. Anxious to get a few Pack knives out too. Three things have slowed progress. 1). Ouch!!!! 2). A few things that just had to be done here about. 3). I had a repeatability issue with my grinding rig. There are several built in adjusts. Those were good. But there was a gremlin I couldn’t find. An intermittent thing (which are THE worst kind). I think I found it this am. A line of milling burr I missed cleaning off the base metal, down inside the clamping head. “Sometimes”, the burr ledge would catch and it seemed like the unit was seated. In reality, it was short sheeting the seating juuuuust a bit. This thing is precise and screw ups can result from misalignment.

This isn’t like you clamp a bar of steel in and come back an hour later to a bucket of shiny blades. I massage the blade done, and it has to come out for heat treating and for the other side, then go back in precisely afterwards to finish. It’s that repeat factor that separates the quality tools from the hammers.

Got to get back and change the bucket! Haha.

Thanks Kurt

Blessings

Gary

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 14, 2020 12:29PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Kurt,

I forgot to mention your infomercial Damascus Chef Knife. I got hooked up to a Face Book Knife Group. There are always guys offering SETS of 4-6 Damascus Chef Knife sets for about $200. They come from one or several of the “...stans”. I think you can get a Replacement Damascus Steel Truck Frame quite reasonably too. The whole country seems to be involved in making Damascus.

I forgot to mention your infomercial Damascus Chef Knife. I got hooked up to a Face Book Knife Group. There are always guys offering SETS of 4-6 Damascus Chef Knife sets for about $200. They come from one or several of the “...stans”. I think you can get a Replacement Damascus Steel Truck Frame quite reasonably too. The whole country seems to be involved in making Damascus.

Re: Edge Testing - Shaving Chips of Cold Rolled Steel!!!  May 14, 2020 04:04AM |

|

Registered: 14 years ago Posts: 1,097 |

Sorry, only registered users may post in this forum.

Online Users

Guests:

24

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021