Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: Did I do THAT ?

|

Did I do THAT ? April 21, 2017 10:27PM |

Registered: 11 years ago Posts: 2,189 |

Well this week at work was very satisfactory . There is 80 ton of steel processed and ready to fit and weld . Who says CNC isn't the way to go ?? I have some repairs scheduled for next week so I did a little stockpiling.

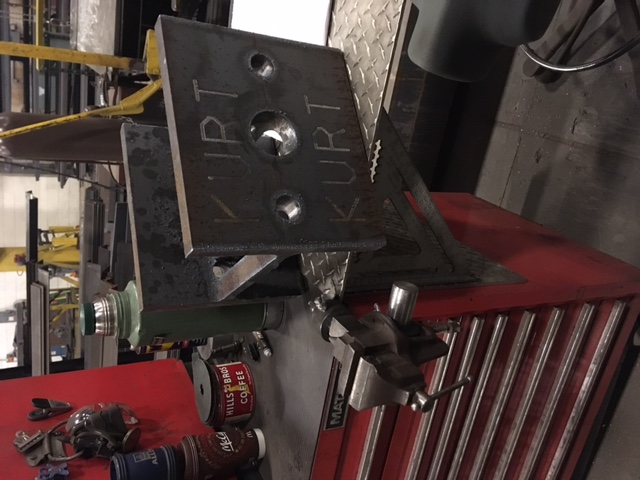

I even got a chance to play around a little with some of the cutoffs pieces .

These beams are W10@100 which means they are 10" tall and weigh 100 lbs per foot . They are pretty beefy as you can tell . The flange thickness is 1-1/8" thick .

It felt like a good week seeing the shop fill up with all that work that I processed AND programmed .

There is a library of templates in the machines computer for programming . The beam in my tool box only took a couple of x&y numbers to make the circles I cut and a simple scribe of my name .

Now I shall rest . What did you all do today ? We know Larry had the day off waiting for new roll of security camera wire .

Thanks

Kurt

I even got a chance to play around a little with some of the cutoffs pieces .

These beams are W10@100 which means they are 10" tall and weigh 100 lbs per foot . They are pretty beefy as you can tell . The flange thickness is 1-1/8" thick .

It felt like a good week seeing the shop fill up with all that work that I processed AND programmed .

There is a library of templates in the machines computer for programming . The beam in my tool box only took a couple of x&y numbers to make the circles I cut and a simple scribe of my name .

Now I shall rest . What did you all do today ? We know Larry had the day off waiting for new roll of security camera wire .

Thanks

Kurt

|

Re: Did I do THAT ? April 22, 2017 02:45AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Kurt,

That is some "Heavy Metal". Wow!

Tell me again, what did you make with your little cut off. Were you practicing processes, or were you making parts for a lunch box or something.

Now, that enormous quantity of colossal I beam materials, is that an order for a project? Will that be bolted with plates? Does anybody do any hot rivet work anymore? That stuff looks like it would hold an aircraft carrier.

Thanks for posting Kurt.

Still mad?

Gary

That is some "Heavy Metal". Wow!

Tell me again, what did you make with your little cut off. Were you practicing processes, or were you making parts for a lunch box or something.

Now, that enormous quantity of colossal I beam materials, is that an order for a project? Will that be bolted with plates? Does anybody do any hot rivet work anymore? That stuff looks like it would hold an aircraft carrier.

Thanks for posting Kurt.

Still mad?

Gary

|

Re: Did I do THAT ? April 22, 2017 01:50PM |

|

Registered: 12 years ago Posts: 326 |

|

Re: Did I do THAT ? April 22, 2017 03:13PM |

Registered: 11 years ago Posts: 2,189 |

Gary

Nah I ain't mad anymore . Hehe I'm glad that it sold but it just proves the point that you gotta be fast AND check often.

The beams are for a big mezzanine platform for the auto industry . Usually that size of beam would be a vertical column but in this case they are horizontal floor beams obviously carrying a heavy load . These beams are far from done there is a lot of fitting and welding to take place before they get to paint . But there will be a lot of bolts !

The piece i made was just checking a process but I plan to make a collet holder for my tool magazine eventually.

As far as hot rivets we've never used then in all my years of erecting . Things change so fast and and on's and changes are made ... with bolts you remove them easily and with riveting not so easy . I've seen them on a lot of bridges and OLD timer box girders. There is an Iron worker festival in Mackinaw city every year ( due to the huge bridge) where they show the old ways . It's a great time and I've gone quite a few times but never competed.

Hey Steve we're almost always hiring here . Some of the older shops guys ( like me ) came from the erecting crews in the field . It's a tuff young mans jobs but very enjoyable.

Thanks

Kurt

Nah I ain't mad anymore . Hehe I'm glad that it sold but it just proves the point that you gotta be fast AND check often.

The beams are for a big mezzanine platform for the auto industry . Usually that size of beam would be a vertical column but in this case they are horizontal floor beams obviously carrying a heavy load . These beams are far from done there is a lot of fitting and welding to take place before they get to paint . But there will be a lot of bolts !

The piece i made was just checking a process but I plan to make a collet holder for my tool magazine eventually.

As far as hot rivets we've never used then in all my years of erecting . Things change so fast and and on's and changes are made ... with bolts you remove them easily and with riveting not so easy . I've seen them on a lot of bridges and OLD timer box girders. There is an Iron worker festival in Mackinaw city every year ( due to the huge bridge) where they show the old ways . It's a great time and I've gone quite a few times but never competed.

Hey Steve we're almost always hiring here . Some of the older shops guys ( like me ) came from the erecting crews in the field . It's a tuff young mans jobs but very enjoyable.

Thanks

Kurt

|

Re: Did I do THAT ? April 22, 2017 08:19PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I wondered if they might be vertical beams cause they were such heavy wall. Boy, that is gonna be a heavy load floor. Hey, that would make a great loft for my lower shop to get my stuff and wood up off the floor. Save me some cut offs and I will weld them together. Haha.

When I was young. First married. I worked for my Dad. Farm machinery business. Customer bought a piece of equipment. Might have been a big plough. They decided they wanted the hitch moved. I forget the details. 45 years ago.

Well, I cut off the hitch from the huge box beam. Cleaned it up. Moved it. Welded it back on. Nice multi pass burned deep. But .... it was an expensive machine. We didn't have a $10k welder. You could tell it had been moved. I decided to just grind it lightly, I wiped on s fillet of body putty along the joints. Then painted it back to match. It looked great. Customer was stunned. Loved it. Then, as soon as they got it home, they decided to move the hitch again. Surprise. Probably to where it had been. Who remembers.

Well, they had a fit with their torch and my body putty. And, they had a fit with my Dad. Of course, like I was trying to hide something. Dad did stick up for me. But it doesn't usually work out to be extra nice - does it? Haha.

So; you save me those drops. Anything over 6". I'll weld them together - paint it nice. Haha OH!!!!! I ALMOST wentbtobthe emojis which would have dumped this!!!!!

When I was young. First married. I worked for my Dad. Farm machinery business. Customer bought a piece of equipment. Might have been a big plough. They decided they wanted the hitch moved. I forget the details. 45 years ago.

Well, I cut off the hitch from the huge box beam. Cleaned it up. Moved it. Welded it back on. Nice multi pass burned deep. But .... it was an expensive machine. We didn't have a $10k welder. You could tell it had been moved. I decided to just grind it lightly, I wiped on s fillet of body putty along the joints. Then painted it back to match. It looked great. Customer was stunned. Loved it. Then, as soon as they got it home, they decided to move the hitch again. Surprise. Probably to where it had been. Who remembers.

Well, they had a fit with their torch and my body putty. And, they had a fit with my Dad. Of course, like I was trying to hide something. Dad did stick up for me. But it doesn't usually work out to be extra nice - does it? Haha.

So; you save me those drops. Anything over 6". I'll weld them together - paint it nice. Haha OH!!!!! I ALMOST wentbtobthe emojis which would have dumped this!!!!!

|

Re: Did I do THAT ? April 23, 2017 07:05PM |

Admin Registered: 15 years ago Posts: 1,489 |

My current project is attempting to correct a poorly bored barrel mortise. It is not centered correctly so I had to bore oversize and I'll sleeve it. At least that is the plan.

Going to install that in a building and immortalize yourself Kurt?

Lon

Edited 1 time(s). Last edit at 04/23/2017 07:06PM by Bigbore.

Going to install that in a building and immortalize yourself Kurt?

Lon

Edited 1 time(s). Last edit at 04/23/2017 07:06PM by Bigbore.

|

Re: Did I do THAT ? April 23, 2017 07:40PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Did I do THAT ? April 23, 2017 11:43PM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: Did I do THAT ? April 24, 2017 02:11PM |

Registered: 11 years ago Posts: 2,189 |

|

Re: Did I do THAT ? April 24, 2017 03:10PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

You referring to the quality milling vises and such, Kurt? I've never had one. I chose rather, to explore the lifestyle of using Chinese Vises AND having groceries. Haha.

Oh, I suspect Lon will tell you he clamped the receiver straight and then booted the properly located socket with his mill, rather then piloting off the incorrectly located bore.

Hey, saw a segment of Dirty Jobs last night where a guy was running a plasma CNC Table Cutter. Can't imagine how clean those cuts are.

Gary

|

Re: Did I do THAT ? April 25, 2017 05:30AM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: Did I do THAT ? April 28, 2017 05:22PM |

Registered: 15 years ago Posts: 2,524 |

|

Re: Did I do THAT ? May 02, 2017 07:22AM |

Registered: 11 years ago Posts: 2,189 |

Hey Sean

Glad your back . I missed reading your posts. Hope your well . Ah the floor only 6" thick and laser flat .

With all the larger pieces there has to be smaller ones . I've been working on these piles and have hundreds of parts to complete . They each have 8 holes 9/16" and a piece mark etched . These parts are killing me . It seems like they just keep coming. This is ONE pile I've got done !

Thanks

Kurt

Glad your back . I missed reading your posts. Hope your well . Ah the floor only 6" thick and laser flat .

With all the larger pieces there has to be smaller ones . I've been working on these piles and have hundreds of parts to complete . They each have 8 holes 9/16" and a piece mark etched . These parts are killing me . It seems like they just keep coming. This is ONE pile I've got done !

Thanks

Kurt

|

Re: Did I do THAT ? May 02, 2017 02:23PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Did I do THAT ? May 02, 2017 05:36PM |

Registered: 11 years ago Posts: 2,189 |

Haha

Yes I'm good with the cranes but .... if I wish hard enough they just disappear after a quick text . The parts are actually to small for the machine . They are 2-3 ft long and 15 lbs per foot . I have to catch them by hand and make a stack on a ( taxi ) beam staged close to torch . The shortest piece the machine is made to run is 8-0" . I technically can't put anything in the torch window ( working area )to catch small pieces for fear of a collision.

I load 50-0"or 60-0" beams on the machine and process all holes and scribes first and THEN the coping machine cuts them up into pieces subtracting a kerf for each cut in between pieces .

The scribing/ etching is done with a plunge cutter insert similar to a carbide triangle for a lathe but more tapered on the relief side . It's all done with the drill head and is able to interpolate. (The piece and drill move at the same time .)

But the coolest part is I'm just a text away from a crane ( material handler person ) . Pretty soon we will all have I pads and won't need prints too . That's what they say !!

Thanks

Kurt

Yes I'm good with the cranes but .... if I wish hard enough they just disappear after a quick text . The parts are actually to small for the machine . They are 2-3 ft long and 15 lbs per foot . I have to catch them by hand and make a stack on a ( taxi ) beam staged close to torch . The shortest piece the machine is made to run is 8-0" . I technically can't put anything in the torch window ( working area )to catch small pieces for fear of a collision.

I load 50-0"or 60-0" beams on the machine and process all holes and scribes first and THEN the coping machine cuts them up into pieces subtracting a kerf for each cut in between pieces .

The scribing/ etching is done with a plunge cutter insert similar to a carbide triangle for a lathe but more tapered on the relief side . It's all done with the drill head and is able to interpolate. (The piece and drill move at the same time .)

But the coolest part is I'm just a text away from a crane ( material handler person ) . Pretty soon we will all have I pads and won't need prints too . That's what they say !!

Thanks

Kurt

|

Re: Did I do THAT ? May 02, 2017 06:10PM |

Registered: 15 years ago Posts: 2,524 |

Wow...looks like enough steel to make your own aircraft carrier! I'll bet when you offload the last of it, your shop gets taller.

Been busy here, trying to line up a contractor and more importantly, the money, to get a foundation wall replaced in our old wreck of a house. The former owners pulled a fast one on us, covered up a failed foundation wall by building another wall inside it. THAT wall looked fine, tile surround for a giant bathtub, no hint of what lay below. The only reason we found the damage was because my wife didn't like the oversized bathtub, wanted to replace it with a vintage tub that didn't take up half the bathroom. When I pulled that out, I discovered extensive water damage, and below that, a real mess. Other than that, we've got company coming and we're trying to get the place safe for guests. For years we've been telling people to come up and see us, it figures that now that we've got the house torn apart, they'd all choose this summer.

Been busy here, trying to line up a contractor and more importantly, the money, to get a foundation wall replaced in our old wreck of a house. The former owners pulled a fast one on us, covered up a failed foundation wall by building another wall inside it. THAT wall looked fine, tile surround for a giant bathtub, no hint of what lay below. The only reason we found the damage was because my wife didn't like the oversized bathtub, wanted to replace it with a vintage tub that didn't take up half the bathroom. When I pulled that out, I discovered extensive water damage, and below that, a real mess. Other than that, we've got company coming and we're trying to get the place safe for guests. For years we've been telling people to come up and see us, it figures that now that we've got the house torn apart, they'd all choose this summer.

|

Re: Did I do THAT ? May 03, 2017 09:50AM |

Registered: 11 years ago Posts: 2,189 |

Man Sean

That really sucks . You never can tell what's hidden beneath either . My old house was built in 1949 and every time I try to fix something I just hafta dig a little deeper . ( into the pocket ) I'm a couple months from paying off a 30 yr mortgage and the place is falling apart . Only good thing is a roof about 5 yrs old . I sure don't want to borrow any or refinance. I've still even got the lime green refrigerator and a one gallon paint can holds the door closed . Does it ever end ???

I'm sure your company will understand . Good luck

Thanks

Kurt

That really sucks . You never can tell what's hidden beneath either . My old house was built in 1949 and every time I try to fix something I just hafta dig a little deeper . ( into the pocket ) I'm a couple months from paying off a 30 yr mortgage and the place is falling apart . Only good thing is a roof about 5 yrs old . I sure don't want to borrow any or refinance. I've still even got the lime green refrigerator and a one gallon paint can holds the door closed . Does it ever end ???

I'm sure your company will understand . Good luck

Thanks

Kurt

|

Re: Did I do THAT ? May 03, 2017 01:14PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I keep coming back to your pics Kurt. Man, that steel just amazes me. At the beginning, I'm amazed the stuff can be made! And it looks true and smooth. Incredible amount of weight to ship and truck and handle. How far is your Shop from the Lakes?

I think you mentioned 60' I beams? Good grief. I'm staggered by the weight of handling stuff like that.

This has been a great thread.

Thanks Kurt,

Gary

I think you mentioned 60' I beams? Good grief. I'm staggered by the weight of handling stuff like that.

This has been a great thread.

Thanks Kurt,

Gary

|

Re: Did I do THAT ? May 03, 2017 05:04PM |

|

Admin Registered: 15 years ago Posts: 665 |

In the early 1960s, my Dad briefly worked at Pittsburgh's famous Jones & Laughlin steel mills for a few summers, like the two generations of my family before him. He recently told me a story about the enormous coils of rolled steel that, once finished, were stood up on end in a huge warehouse waiting for transport. As each coil was set down on the shop floor, a couple of guys would go around it and level it out by banging wedges under certain spots with a mallet. These things each weighed many tons and were easily eight feet in diameter and at least that tall.

Apparently during one of his shifts, someone hadn't done a good job of leveling out one of the coils, and it shifted and pinned one of the supervisors against a neighboring coil and crushed him to death. The strange thing was that he didn't die right away -- he was still conscious, and he didn't really feel any pain, but the thing of course trapped him and mortally wounded him and by the time they could get him loose he was dead.

My Dad's Dad -- my grandfather, who just passed away a few months ago at the age of 102 -- worked the open hearth at J & L for 40+ years. I have a few stories about that as well. Be careful with this stuff!

-- Jim

Apparently during one of his shifts, someone hadn't done a good job of leveling out one of the coils, and it shifted and pinned one of the supervisors against a neighboring coil and crushed him to death. The strange thing was that he didn't die right away -- he was still conscious, and he didn't really feel any pain, but the thing of course trapped him and mortally wounded him and by the time they could get him loose he was dead.

My Dad's Dad -- my grandfather, who just passed away a few months ago at the age of 102 -- worked the open hearth at J & L for 40+ years. I have a few stories about that as well. Be careful with this stuff!

-- Jim

|

Re: Did I do THAT ? May 03, 2017 11:10PM |

Registered: 11 years ago Posts: 2,189 |

Hi Jim

Yes the big mills do some crazy big steel . It's a very dangerous kinda job . About 2 years ago the company that galvanized our steel had a terrible tragedy . A rack they were loading either tipped over or got hit with an overhead crane falling on a man . Same thing he was pinned but alive and talking . They shut the plant down and called his family in and a priest/ pastor . He lived long enough for that but then when the load got moved he expired . Very sad .

Gary

Those larger beams we fabricated weighed 5000 lbs each . We have 20,000 lb cranes but the rigging weighs a couple hundred lbs so we could only pick 3 at a time . The mills have a tolerance and we do have to reject them sometimes. They usually get damaged handling . Semi trailers at 48-0" so a 60-0" beam hangs over and harmonically bounces all the way down the highway setting in a camber or bend .

Now I've done some BIG beams (W40 inches tall ) and so I'm not easily impressed but these were thick AND we have a lot of the same kind . We aren't very far from Detroit just a couple hours north . But most of our steel gets hauled right down the highway to and fro !

It's good to be busy !!!'

Thanks

Kurt

Yes the big mills do some crazy big steel . It's a very dangerous kinda job . About 2 years ago the company that galvanized our steel had a terrible tragedy . A rack they were loading either tipped over or got hit with an overhead crane falling on a man . Same thing he was pinned but alive and talking . They shut the plant down and called his family in and a priest/ pastor . He lived long enough for that but then when the load got moved he expired . Very sad .

Gary

Those larger beams we fabricated weighed 5000 lbs each . We have 20,000 lb cranes but the rigging weighs a couple hundred lbs so we could only pick 3 at a time . The mills have a tolerance and we do have to reject them sometimes. They usually get damaged handling . Semi trailers at 48-0" so a 60-0" beam hangs over and harmonically bounces all the way down the highway setting in a camber or bend .

Now I've done some BIG beams (W40 inches tall ) and so I'm not easily impressed but these were thick AND we have a lot of the same kind . We aren't very far from Detroit just a couple hours north . But most of our steel gets hauled right down the highway to and fro !

It's good to be busy !!!'

Thanks

Kurt

|

Re: Did I do THAT ? May 04, 2017 03:24PM |

Registered: 15 years ago Posts: 2,524 |

Thanks for the kind words Kurt. You're totally right about old houses, every time you open up something it's always more complicated and more expensive to fix that you'd hoped. Gary could undoubtedly testify to this at length...if he hasn't already blocked all those memories due to their traumatic nature! The place we're in was built in '46 as a beach cottage, using wood salvaged from a late 1800's era fish cannery that got knocked down when it closed. Apparently they barged pieces of the place all over Juneau, must have been a bargain at the time. It was remodeled into a full-time house somewhere in the 60's or 70s, another owner enclosed the lower floor in the 80's, and as a result there's all kinds of "character" that got built-in over the years.

Too bad I can't get a hold of some of those beams to hold up my front porch! Might be a BIT of overkill though... Probably only need one to hold up the whole house!

Probably only need one to hold up the whole house!

Too bad I can't get a hold of some of those beams to hold up my front porch! Might be a BIT of overkill though...

Probably only need one to hold up the whole house!

Probably only need one to hold up the whole house!

|

Re: Did I do THAT ? May 05, 2017 01:44PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I'm sure you know, Sean: the key to working alone with heavy beams in awkward places is .... "laminate in place". Build the beam in its required position, one ply at a time. It's worked for me (and those who came after) many times.

Yes, I seriously do avoid thoughts down memory lane's dark alley of horrors. I had to turn in my Charm/Character/Pride ... Card ... in an effort to save my last 12% of sanity. Even now, I skate by the endless Real Estate streamed shows on the weekends. Blowing by, I still hear how prices are up and inventory is very low. And how I managed to sell at the bottom of the market. Whaaaaa whaaaaa whaaaaa whaaa......,,

Yes, I seriously do avoid thoughts down memory lane's dark alley of horrors. I had to turn in my Charm/Character/Pride ... Card ... in an effort to save my last 12% of sanity. Even now, I skate by the endless Real Estate streamed shows on the weekends. Blowing by, I still hear how prices are up and inventory is very low. And how I managed to sell at the bottom of the market. Whaaaaa whaaaaa whaaaaa whaaa......,,

Sorry, only registered users may post in this forum.

Online Users

Guests:

8

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021