Home

>

Airgun Rendezvous Main Forum

>

Topic

The Speed of Various Projects.  . Liberty Case

. Liberty Case

The Speed of Various Projects.  . Liberty Case . Liberty Case May 18, 2022 09:24PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I know it’s hard for you to anticipate how quickly a project might be complete. Let’s use this LIBERTY CASE for an example. The number of weeks we’ve been talking about it is not an accurate indication of how long one case will take. Yes, there has been a lot of tooling to make. That still doesn’t accurately project a build time. I’ve had several things to take care of during this time period, and I’ve had some medical details to sort out. A few more cases will fill in the time cards better. Today, for example; was eaten up by needing to fix a poorly engineered electric window in Kelly’s minivan. She’s going to our Grandson’s graduation in a couple of days. The window died in a grinding pathetic mess. Off the track with braided cable and plastic gears and pulleys. Ahhhhhh, heirloom quality if I never saw it! What a joke. So it was up to me to get it in track, elevated, and wedged into place awaiting the pros who work on such junk. It’s stuff like that which eats shop days. But you have those too! Let’s talk about the Case ....

Thank you so much for your comments. I’m glad you like the Liberty Case. I’m real pleased too.

The manufacture of precise tooling and jigs has taken time. That’s done, to my foresight at this point. You can only move the metal when it’s precisely and firmly held in exact alignment. The shape you want is waiting for the metal to be driven into the void or stretched over the male position of a die set. Critical to the technique is the hardness of the metal. If that hardness has not been properly corrected, you will destroy your previous work. Nickel is tricky to anneal. You must be very careful of the metal temperature. In addition, you must keep track of the changing hardness as you work. When you bend, stretch, or compress the metal, you “work harden” said material. Before moving to the next step, it’s critical that you return the metal to its annealed state. If you don’t remove the induced “work hardness”, the metal will not “flow” or move in a smooth arc. The hard area will stop the arc or fold. Applying additional force will fracture the material. You have to aware of the feedback your tools are exhibiting. The tooling will almost always have the power to easily overcome the resistance of “work hardened material”, but the next thing you notice is that resistance goes to zero, you may hear a faint snap ... and you’ve just been set back a day’s work.

When you make a complex product like the “Liberty Case”, where everything traces its origin to a single flat sheet of material, then each procedure you initiate, risks all results that you have gained before. I’ll add in here, why you honestly access your “status”, and you don’t work on certain projects unless you are at 85% minimum status. Otherwise, your first half an hour of work may set you back two good day’s of work.

I can’t wait to fold the case and hear that distinct “Click” of the latch. It’s not far off now. Please stop back.

Blessings

Gary

Thank you so much for your comments. I’m glad you like the Liberty Case. I’m real pleased too.

The manufacture of precise tooling and jigs has taken time. That’s done, to my foresight at this point. You can only move the metal when it’s precisely and firmly held in exact alignment. The shape you want is waiting for the metal to be driven into the void or stretched over the male position of a die set. Critical to the technique is the hardness of the metal. If that hardness has not been properly corrected, you will destroy your previous work. Nickel is tricky to anneal. You must be very careful of the metal temperature. In addition, you must keep track of the changing hardness as you work. When you bend, stretch, or compress the metal, you “work harden” said material. Before moving to the next step, it’s critical that you return the metal to its annealed state. If you don’t remove the induced “work hardness”, the metal will not “flow” or move in a smooth arc. The hard area will stop the arc or fold. Applying additional force will fracture the material. You have to aware of the feedback your tools are exhibiting. The tooling will almost always have the power to easily overcome the resistance of “work hardened material”, but the next thing you notice is that resistance goes to zero, you may hear a faint snap ... and you’ve just been set back a day’s work.

When you make a complex product like the “Liberty Case”, where everything traces its origin to a single flat sheet of material, then each procedure you initiate, risks all results that you have gained before. I’ll add in here, why you honestly access your “status”, and you don’t work on certain projects unless you are at 85% minimum status. Otherwise, your first half an hour of work may set you back two good day’s of work.

I can’t wait to fold the case and hear that distinct “Click” of the latch. It’s not far off now. Please stop back.

Blessings

Gary

Re: The Speed of Various Projects.  . Liberty Case . Liberty Case May 18, 2022 09:31PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

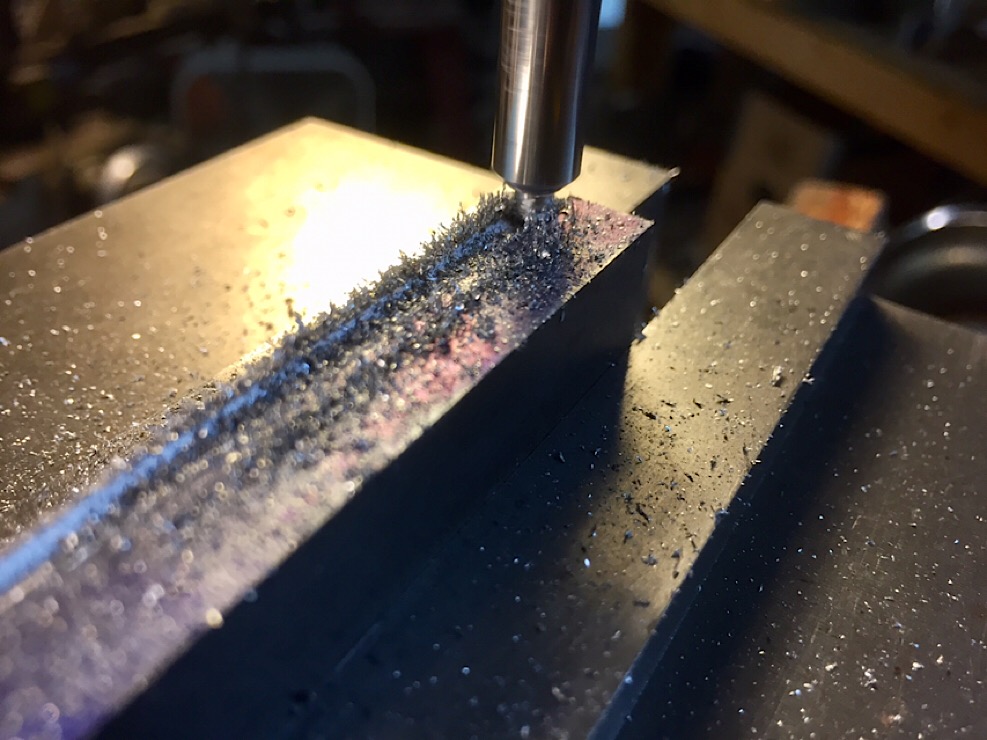

I had to make a Round Nosed Mill Cutter of .140” diameter in order to make tooling. Then use that tool I just made, to Mill a precise steel groove that I needed ... to make another tool. It all takes a while, but it “stays done”. Ha. I’ll be able to use these tools for the duration. And someone else can get decade’s from them too.

Sorry, only registered users may post in this forum.

Online Users

Guests:

15

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021