Home

>

Airgun Rendezvous Main Forum

>

Topic

Family Pics ... Mdl 97 Group Pics

|

Family Pics ... Mdl 97 Group Pics October 07, 2015 12:19AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Family Pics ... October 07, 2015 01:20AM |

Registered: 11 years ago Posts: 351 |

|

Re: Family Pics ... October 07, 2015 01:52AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Family Pics ... October 07, 2015 11:46PM |

Registered: 12 years ago Posts: 2,189 |

|

Re: Family Pics ... October 08, 2015 02:20AM |

Registered: 13 years ago Posts: 780 |

|

Re: Family Pics ... October 08, 2015 10:04AM |

Registered: 9 years ago Posts: 683 |

|

Re: Family Pics ... October 08, 2015 01:19PM |

Registered: 12 years ago Posts: 2,189 |

|

Re: Family Pics ... October 08, 2015 03:00PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Kurt,

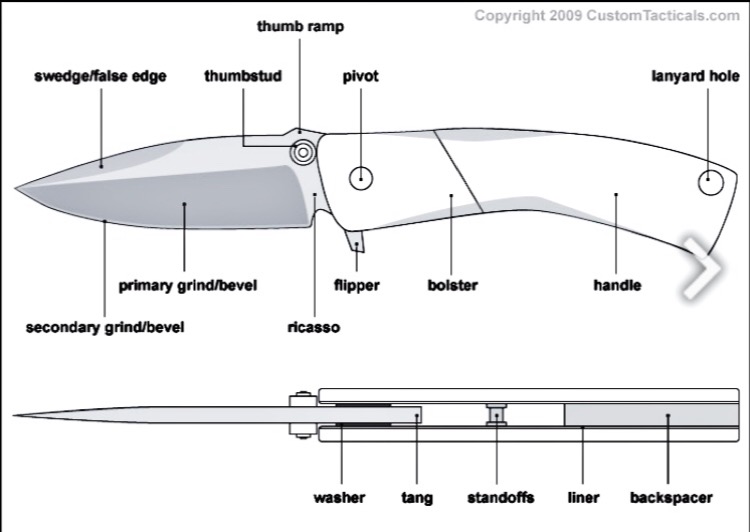

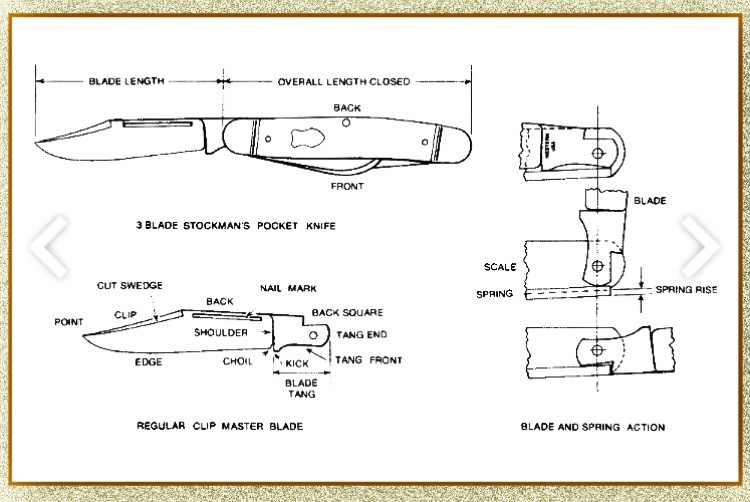

I'd like to draw up a chart with parts and notations on it. For now, I found these two pics online.

I think your question had to do with what you see, when looking at the length of the handle. At the Front (blade end) you see a metal BOLSTER area. Next, in length, you see a SCALE. That scale can go clear to the end of the handle, or there may be another bolster area at the back end of the handle. I just referred to what you see, to make a distinction between the knives in the photo.

As you know, bolsters can be made seperately and attached to the liners by silver soldering or by mechanical means (rivets, machine screws), or a solid material can be machined, to produce the area where scale material is fitted. The highest form (and most difficult to properly execute) is the "INNERFRAME", where a solid material is machined to produce a cavity (within the perimeter of the handle) where a perfectly matched scale material is inlaid. This type shows metal all around a geometric shaped inlay. Your Mdl 97, Kurt; is an "Innerframe" design.

My Innerframe 97

Kurt's Innerframe 97

Gary

I'd like to draw up a chart with parts and notations on it. For now, I found these two pics online.

I think your question had to do with what you see, when looking at the length of the handle. At the Front (blade end) you see a metal BOLSTER area. Next, in length, you see a SCALE. That scale can go clear to the end of the handle, or there may be another bolster area at the back end of the handle. I just referred to what you see, to make a distinction between the knives in the photo.

As you know, bolsters can be made seperately and attached to the liners by silver soldering or by mechanical means (rivets, machine screws), or a solid material can be machined, to produce the area where scale material is fitted. The highest form (and most difficult to properly execute) is the "INNERFRAME", where a solid material is machined to produce a cavity (within the perimeter of the handle) where a perfectly matched scale material is inlaid. This type shows metal all around a geometric shaped inlay. Your Mdl 97, Kurt; is an "Innerframe" design.

My Innerframe 97

Kurt's Innerframe 97

Gary

|

Re: Family Pics ... October 08, 2015 03:01PM |

Registered: 9 years ago Posts: 683 |

Hey Kurt,

You kind of lost me on that. I am not an expert, but on some knives the bolsters are actually separate pieces that go on the ends to more-or-less reinforce the 'frame,' or to provide more stock for riviting or pinning it all together. They are ofter also decorative and have many traditional shapes and styles.

In the old days you had a set of (usually) brass frame pieces, and or 'liners' (usually made out of flat stock, and in later years and today, also made of steel, stainless steel or titanium) and the 'works' were inside, or between, these two pieces. Often those parts were simply punched out of thin stock by huge machines and then layered together and pinned or rivited into the final product. The bolsters could have been pinned on, soldered on, or even slotted with keyholes to mount them.

For example if it was a single blade ordinary folding pocket knife being made you had the blade pivot from it's end into one side (the open side) of the frame. On the other side (the "back spline" if I understand you correctly) you had the spring and spacers. The spring acted directly on the end of the blade and the spacers held it in place as the blade opened and closed. These are often called 'slip joint' knives. This method is still very common today, and most Case brand [copywrited] (and other brand) folding pocket knifes are made that way.

On that style of knife the blade pivoted from the end of the handle, under spring pressure. The pivot bolster, handle scales and then the end bolster were rivited to the frame to make the final knife. The handle pins only went through one side of the frame (and handle scale) and you could look inside the handle and see where they were located in the liner, The bolsters were the only place where the pins when through the entire knife. The blade pivoted on one of those bolster pins and the spring often pivoted on one of the handle pins that was located in the center of the back side of the knife.

I believe Gary often makes his frames with 'internal bolsters' where all of those pieces are combined and machined out of one piece of metal all at the same time. It's a much more difficult method to use in order to get everything exactly right. With the stacked and pinned together method you could to 'simply' (for lack of a better term) sand or file down any proud edges of the finished piece to make it look good.

On modern knives, with a different type of construction like a 'Walker' lock (which is a flat spring type liner, or part of the internal frame, that sticks out inside the handle behind the base of the blade to lock it in place when open) you often have a gap in the back of the knife as you have no other parts to fit in there. On a Walker lock, once the blade is open and locked in place, you have to move the spring liner to the side in order to close the knife. This type of construction doesn't need the 'back' spring that the slip joint uses, nor the spacers to hold it in place, so it is often left open where you can see through it.

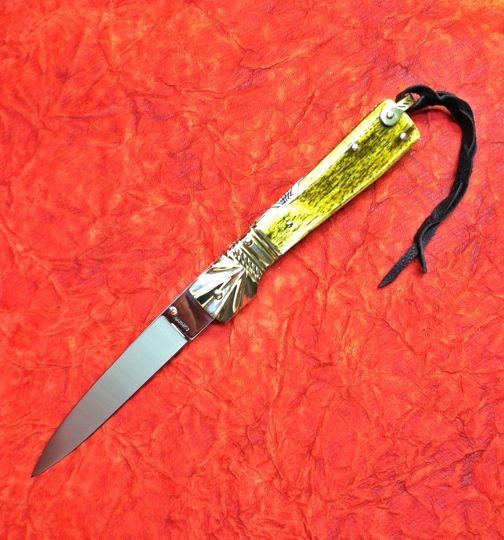

Sooo, on the bottom knife in the above picture you have the metal parts (one set of bolsters on each side of that end only) where the blade pivots and where the actuation button is, (for strength possibly and also to house the button mechanism), and then you have the "fossilized sketer tusk" handles which go to the far end (or bottom) of the handle and have no bolsters located there. They aren't really needed there anyway, and this is all part of the style or 'look' of the piece. The other two knives pictured have bolsters on both ends, and in this case they are made internal to the frame rather than added on by some attachment method, and are also part of the 'style' of those knives.

Anyway,like I said, I'm not an expert, and if I'm not correct (anyone) please feel free to jump in and let me know. I'm just trying to help clarify the bolster issue and unfortunately I get a little long winded sometimes . I hope it helped rather than muddied up the waters Kurt.

. I hope it helped rather than muddied up the waters Kurt.

Thanks,

Jeff

Edited 3 time(s). Last edit at 10/08/2015 06:36PM by jcwward2.

You kind of lost me on that. I am not an expert, but on some knives the bolsters are actually separate pieces that go on the ends to more-or-less reinforce the 'frame,' or to provide more stock for riviting or pinning it all together. They are ofter also decorative and have many traditional shapes and styles.

In the old days you had a set of (usually) brass frame pieces, and or 'liners' (usually made out of flat stock, and in later years and today, also made of steel, stainless steel or titanium) and the 'works' were inside, or between, these two pieces. Often those parts were simply punched out of thin stock by huge machines and then layered together and pinned or rivited into the final product. The bolsters could have been pinned on, soldered on, or even slotted with keyholes to mount them.

For example if it was a single blade ordinary folding pocket knife being made you had the blade pivot from it's end into one side (the open side) of the frame. On the other side (the "back spline" if I understand you correctly) you had the spring and spacers. The spring acted directly on the end of the blade and the spacers held it in place as the blade opened and closed. These are often called 'slip joint' knives. This method is still very common today, and most Case brand [copywrited] (and other brand) folding pocket knifes are made that way.

On that style of knife the blade pivoted from the end of the handle, under spring pressure. The pivot bolster, handle scales and then the end bolster were rivited to the frame to make the final knife. The handle pins only went through one side of the frame (and handle scale) and you could look inside the handle and see where they were located in the liner, The bolsters were the only place where the pins when through the entire knife. The blade pivoted on one of those bolster pins and the spring often pivoted on one of the handle pins that was located in the center of the back side of the knife.

I believe Gary often makes his frames with 'internal bolsters' where all of those pieces are combined and machined out of one piece of metal all at the same time. It's a much more difficult method to use in order to get everything exactly right. With the stacked and pinned together method you could to 'simply' (for lack of a better term) sand or file down any proud edges of the finished piece to make it look good.

On modern knives, with a different type of construction like a 'Walker' lock (which is a flat spring type liner, or part of the internal frame, that sticks out inside the handle behind the base of the blade to lock it in place when open) you often have a gap in the back of the knife as you have no other parts to fit in there. On a Walker lock, once the blade is open and locked in place, you have to move the spring liner to the side in order to close the knife. This type of construction doesn't need the 'back' spring that the slip joint uses, nor the spacers to hold it in place, so it is often left open where you can see through it.

Sooo, on the bottom knife in the above picture you have the metal parts (one set of bolsters on each side of that end only) where the blade pivots and where the actuation button is, (for strength possibly and also to house the button mechanism), and then you have the "fossilized sketer tusk" handles which go to the far end (or bottom) of the handle and have no bolsters located there. They aren't really needed there anyway, and this is all part of the style or 'look' of the piece. The other two knives pictured have bolsters on both ends, and in this case they are made internal to the frame rather than added on by some attachment method, and are also part of the 'style' of those knives.

Anyway,like I said, I'm not an expert, and if I'm not correct (anyone) please feel free to jump in and let me know. I'm just trying to help clarify the bolster issue and unfortunately I get a little long winded sometimes

. I hope it helped rather than muddied up the waters Kurt.

. I hope it helped rather than muddied up the waters Kurt.

Thanks,

Jeff

Edited 3 time(s). Last edit at 10/08/2015 06:36PM by jcwward2.

|

Re: Family Pics ... October 12, 2015 11:29PM |

Registered: 13 years ago Posts: 780 |

|

Re: Family Pics ... Mdl 97 Group Pics October 08, 2015 03:07PM |

Registered: 9 years ago Posts: 683 |

|

Re: Family Pics ... Mdl 97 Group Pics October 08, 2015 08:16PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Jeff,

I give you an A+

I didn't beat you. You did me the favor of typing it all out. Thanks much.

I have made, and do make - ALL of the construction methods you mentioned. You gave a good explanation. I'll grab an example.

This one ... Remember "The Perfect Knife" - has seperate flat brass liners ... with thicker brass bolsters (one each side of course), and the bolsters are Silver Soldered onto the liners. That makes the frame. The bone scales are glued and riveted to the frame. The front bolster Machine Screw is only a thru rod, in TENSION, holding the sides of the knife together. This Machine Screw goes thru the center of a steel HUB. The blade has a hole they it the size of the hub, so the blade rotates around and on that large hub diameter. Now, that hub isn't just slipping around on the screw thru it's center. The ends of the hub are each set into machined sockets in the liners. So, you have a very strong, large diameter hub, inlet into the liners, and the machine screw doesn't even touch the inside of the hole. It's purely a side to side tension member. At the back of the knife is a small spacer and another tension screw. This small hub is not inlaid.

Another totally traditional 19th century construction.

Here is a knife where the bolsters and liner are seperate. Stainless liners. Hard Aluminum bolsters. The bolsters are held in place with machine screws. This is the Liner Lock or what Jeff called the "Walker Lock". Michael Walker is a fine custom maker. He popularized this lock design in the early 80's. Around that time, probably 82-83, I drove to the Dallas Custom Knife Guild Show. Afterwards, I stayed with Michael for about a week; in Taos, New Mexico. While there, a Celestial Event known as "The Harmonic Convergence" was taking place. The area of Taos is a good place to find folks interested in mystical things. In the Harmonic Convergence, the first five planets align in a string, from the Sun outwards. Some like to attribute powers to the event. Micheal and I, with his wife Patrica - made a custom knife to honor the event. He and I found a length of heavy salvage braided cable, along a desert road. I his electric heat treat oven, we managed to get it to welding heat. I forge welded it into wire Damascus, on a length of railroad track anvil. He made a large titanium liner lock case. I heat treated the blade. I inlaid Anvient Ivory in the handle, and relief carved an ancient Hunter viewing a meteor. Patricia engraved and anodized the bolsters. We inlaid semi-precious cut and polished stones into the blade. Colors and Sizes relative to represent the Sun and each planet.

The long/short. We finished it. I arranged immediately to sell it, sight unseen (1982 - land line phone). We all split it up and did quite well.

More types later. Thanks Jeff, Julio, Kurt.

Gary

Edited 3 time(s). Last edit at 10/08/2015 08:29PM by barnespneumatic.

I give you an A+

I didn't beat you. You did me the favor of typing it all out. Thanks much.

I have made, and do make - ALL of the construction methods you mentioned. You gave a good explanation. I'll grab an example.

This one ... Remember "The Perfect Knife" - has seperate flat brass liners ... with thicker brass bolsters (one each side of course), and the bolsters are Silver Soldered onto the liners. That makes the frame. The bone scales are glued and riveted to the frame. The front bolster Machine Screw is only a thru rod, in TENSION, holding the sides of the knife together. This Machine Screw goes thru the center of a steel HUB. The blade has a hole they it the size of the hub, so the blade rotates around and on that large hub diameter. Now, that hub isn't just slipping around on the screw thru it's center. The ends of the hub are each set into machined sockets in the liners. So, you have a very strong, large diameter hub, inlet into the liners, and the machine screw doesn't even touch the inside of the hole. It's purely a side to side tension member. At the back of the knife is a small spacer and another tension screw. This small hub is not inlaid.

Another totally traditional 19th century construction.

Here is a knife where the bolsters and liner are seperate. Stainless liners. Hard Aluminum bolsters. The bolsters are held in place with machine screws. This is the Liner Lock or what Jeff called the "Walker Lock". Michael Walker is a fine custom maker. He popularized this lock design in the early 80's. Around that time, probably 82-83, I drove to the Dallas Custom Knife Guild Show. Afterwards, I stayed with Michael for about a week; in Taos, New Mexico. While there, a Celestial Event known as "The Harmonic Convergence" was taking place. The area of Taos is a good place to find folks interested in mystical things. In the Harmonic Convergence, the first five planets align in a string, from the Sun outwards. Some like to attribute powers to the event. Micheal and I, with his wife Patrica - made a custom knife to honor the event. He and I found a length of heavy salvage braided cable, along a desert road. I his electric heat treat oven, we managed to get it to welding heat. I forge welded it into wire Damascus, on a length of railroad track anvil. He made a large titanium liner lock case. I heat treated the blade. I inlaid Anvient Ivory in the handle, and relief carved an ancient Hunter viewing a meteor. Patricia engraved and anodized the bolsters. We inlaid semi-precious cut and polished stones into the blade. Colors and Sizes relative to represent the Sun and each planet.

The long/short. We finished it. I arranged immediately to sell it, sight unseen (1982 - land line phone). We all split it up and did quite well.

More types later. Thanks Jeff, Julio, Kurt.

Gary

Edited 3 time(s). Last edit at 10/08/2015 08:29PM by barnespneumatic.

|

Re: Family Pics ... Mdl 97 Group Pics October 08, 2015 04:43PM |

Registered: 13 years ago Posts: 780 |

|

Re: Family Pics ... Mdl 97 Group Pics October 09, 2015 12:08AM |

Registered: 9 years ago Posts: 683 |

Hey Gary,

Thanks for the great grade . I never did that well in school... I guess I should gone to the Barnes School, lol. I enjoyed writing it and I really appreciate the confirmation. That story of working with Michael Walker is wonderful. What a week that must have been. You have to find a picture of that knife, it sounds awesome. Other than that you have to stop showing all of those pictures - gees those are some beautiful knifes!!! I want them all. Your construction techniques never fail to amaze me. Thanks for that post!

. I never did that well in school... I guess I should gone to the Barnes School, lol. I enjoyed writing it and I really appreciate the confirmation. That story of working with Michael Walker is wonderful. What a week that must have been. You have to find a picture of that knife, it sounds awesome. Other than that you have to stop showing all of those pictures - gees those are some beautiful knifes!!! I want them all. Your construction techniques never fail to amaze me. Thanks for that post!

Later,

Jeff

Thanks for the great grade

. I never did that well in school... I guess I should gone to the Barnes School, lol. I enjoyed writing it and I really appreciate the confirmation. That story of working with Michael Walker is wonderful. What a week that must have been. You have to find a picture of that knife, it sounds awesome. Other than that you have to stop showing all of those pictures - gees those are some beautiful knifes!!! I want them all. Your construction techniques never fail to amaze me. Thanks for that post!

. I never did that well in school... I guess I should gone to the Barnes School, lol. I enjoyed writing it and I really appreciate the confirmation. That story of working with Michael Walker is wonderful. What a week that must have been. You have to find a picture of that knife, it sounds awesome. Other than that you have to stop showing all of those pictures - gees those are some beautiful knifes!!! I want them all. Your construction techniques never fail to amaze me. Thanks for that post!

Later,

Jeff

|

Re: Family Pics ... Mdl 97 Group Pics October 09, 2015 06:49PM |

Registered: 12 years ago Posts: 2,189 |

Thanks for all the info guys

I'm not to up on the terminology but I will read the post a couple more times to absorb it all . Sorry it took so long to get back but I had a crazy afternoon at work shipping out semi's of steel , late arrivals , over weight, missing parts and all .

The story about your knife build is great . I think I would have a hard time sharing the glory with other artist's on such a small but big project . I like Jeff and I'm sure others would love to see a photo but.... building a knife with obtaininum has to be cool .

So back to the bolster issues I'm having ,would the 2 bolster knife in photo technically have four bolsters ? Two on each side ? Maybe I'm confusing double with 2 in my head

Must get coffee !!!!!

Thanks

Kurt

I'm not to up on the terminology but I will read the post a couple more times to absorb it all . Sorry it took so long to get back but I had a crazy afternoon at work shipping out semi's of steel , late arrivals , over weight, missing parts and all .

The story about your knife build is great . I think I would have a hard time sharing the glory with other artist's on such a small but big project . I like Jeff and I'm sure others would love to see a photo but.... building a knife with obtaininum has to be cool .

So back to the bolster issues I'm having ,would the 2 bolster knife in photo technically have four bolsters ? Two on each side ? Maybe I'm confusing double with 2 in my head

Must get coffee !!!!!

Thanks

Kurt

|

Re: Family Pics ... Mdl 97 Group Pics October 09, 2015 08:24PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Family Pics ... Mdl 97 Group Pics October 09, 2015 07:13PM |

Registered: 9 years ago Posts: 683 |

|

Re: Family Pics ... Mdl 97 Group Pics October 13, 2015 08:39AM |

Registered: 9 years ago Posts: 683 |

Sorry, only registered users may post in this forum.

Online Users

Guests:

16

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021

.

.  .

.