Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: Back in the saddle

|

Back in the saddle April 11, 2012 12:58AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Back in the saddle April 11, 2012 02:43AM |

|

Registered: 14 years ago Posts: 1,097 |

|

Re: Back in the saddle April 11, 2012 03:38AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Back in the saddle April 11, 2012 05:58AM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: Back in the saddle April 11, 2012 06:13PM |

|

Registered: 14 years ago Posts: 1,097 |

I must need new glasses. I thought the cherry cutters looked odd, didn't realize a shop cloth was over the actual cutting contour until I took another look at the pic this morning.

Must be the stress of being at work and not able to work on and shoot airguns....

Gary, looking forward to seeing the rifle and target groups.

Must be the stress of being at work and not able to work on and shoot airguns....

Gary, looking forward to seeing the rifle and target groups.

|

Re: Back in the saddle April 11, 2012 07:06PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Yeah. No use to give away work to the ones who don't want to do the research and field work. Of course, some of the slug designs that don't fly might occasionally leak ...  . Haha

. Haha

That shop cloth is leather guys. You know I treat you better then that. Haha. If I mask things, I do it with class!

Gary

. Haha

. Haha

That shop cloth is leather guys. You know I treat you better then that. Haha. If I mask things, I do it with class!

Gary

|

Re: Back in the saddle April 12, 2012 01:33AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Each end of the mold carries three cavities. Different design each end - two total. Six total cavities.

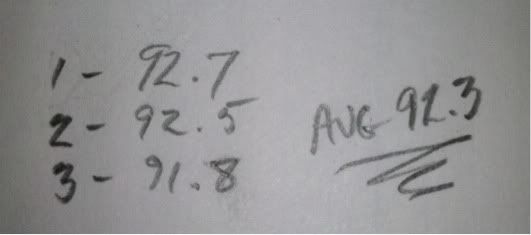

Each are cut separately, one at a time. Trick is to get them as close as possible to identical. Here's the combines weights of three. Average shown.

Then here are the individual slugs from this casting session.

Very close. Now we will see if they fly.

Gary

|

Re: Back in the saddle April 12, 2012 02:07PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Back in the saddle April 11, 2012 11:41PM |

|

Registered: 14 years ago Posts: 1,097 |

Gary,

Your right about showing to much online. I have learned to be more cautious about details I post. My hats off to you making everything from scratch. Only years of practical experience allow for making a cherry and mold to desired specs without making scrap.

I started experimenting with big bore barrels a few years ago. I realize now that I made many mistakes with the first barrels I tried button rifling with. Hopefully later this year I can put what I learned to practical use.

Have a good week.

P. S. First time making a post with my iPhone. Really neat!

Your right about showing to much online. I have learned to be more cautious about details I post. My hats off to you making everything from scratch. Only years of practical experience allow for making a cherry and mold to desired specs without making scrap.

I started experimenting with big bore barrels a few years ago. I realize now that I made many mistakes with the first barrels I tried button rifling with. Hopefully later this year I can put what I learned to practical use.

Have a good week.

P. S. First time making a post with my iPhone. Really neat!

|

Re: Back in the saddle April 12, 2012 12:16AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I completed the mold this evening, and cast a few first run slugs from it awhile ago. It drops one slug @ .310" and the other at .311". Both size beautifully to .307" if desired.

One slug is 84.5 grains and the other 91.22 grains. However; I cleaned the pot, got the crud off the walls and bottom (I'm rusty - forgot that) and gained another 100 degrees. Might get more. With the lead hotter, and knowing the slugs are correct now - I can continue and cast a batch. They will be more clean and full. Might gain a grain or two. We'll see.

Should be what I need for the Barnes 308 Series. I've needed to complete this missing link for the several in the field, the couple on the Reverse Ledger, and the ones in the ledger build parts tubes.

I'll get some into the air asap. Hope they fly accurately.

Had the power company and electrician here this am. Finally had a really fine experience with a hired expert. That's probably why it snowed here today (just a bit). So, now I have new upgraded service to the property. I think I'll put 200 Watt light bulbs in every socket!

So, now I have new upgraded service to the property. I think I'll put 200 Watt light bulbs in every socket!

Pedro - hope you enjoy your iphone. I've enjoyed mine. Great tool.

Gary

One slug is 84.5 grains and the other 91.22 grains. However; I cleaned the pot, got the crud off the walls and bottom (I'm rusty - forgot that) and gained another 100 degrees. Might get more. With the lead hotter, and knowing the slugs are correct now - I can continue and cast a batch. They will be more clean and full. Might gain a grain or two. We'll see.

Should be what I need for the Barnes 308 Series. I've needed to complete this missing link for the several in the field, the couple on the Reverse Ledger, and the ones in the ledger build parts tubes.

I'll get some into the air asap. Hope they fly accurately.

Had the power company and electrician here this am. Finally had a really fine experience with a hired expert. That's probably why it snowed here today (just a bit).

So, now I have new upgraded service to the property. I think I'll put 200 Watt light bulbs in every socket!

So, now I have new upgraded service to the property. I think I'll put 200 Watt light bulbs in every socket!

Pedro - hope you enjoy your iphone. I've enjoyed mine. Great tool.

Gary

|

Re: Back in the saddle April 12, 2012 03:42PM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: Back in the saddle April 12, 2012 03:50PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Back in the saddle April 12, 2012 12:10AM |

Registered: 15 years ago Posts: 234 |

|

Re: Back in the saddle April 12, 2012 12:22AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Back in the saddle April 19, 2012 11:05AM |

Registered: 15 years ago Posts: 438 |

Sorry, only registered users may post in this forum.

Online Users

Guests:

24

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021

That's real patina!!

That's real patina!!