Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: Progress in Studio Shop NOW WITH PICS!

|

Progress in Studio Shop NOW WITH PICS! December 10, 2012 11:07PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

PICS NOW POSTED!

But I've done a bunch of wiring. Running 220 lines and 110 thru the walls, and ceiling. Fighting the 9 1/2" insulation blankets up there. They are marked R-30 so that's nice once you aren't handling them.

The Power light indicating I have 220 power to my big lathe. yeah.

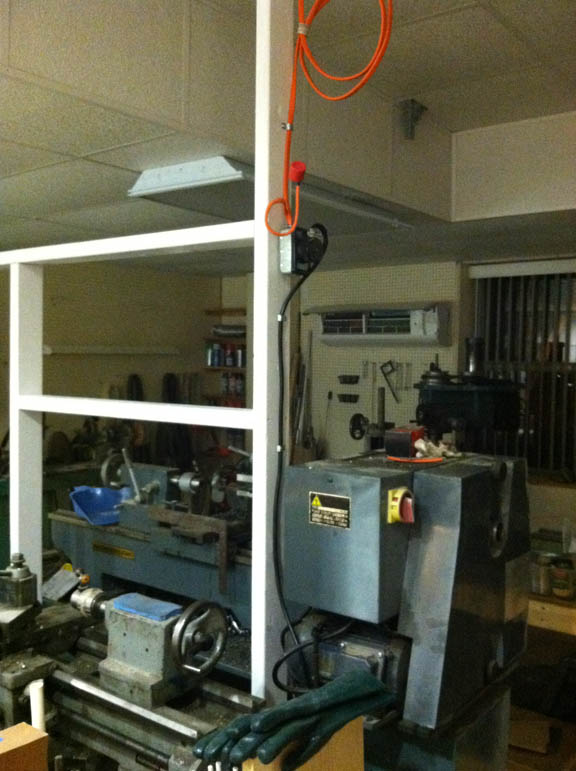

The frame between the two larger lathes - which are back to back. This will hold work lights - and tool racks for the immediate tools being used for each job session. The coils of wire are for the ability to "roll out" the lathes for cleaning, etc. Both are on heavy wheeled carraiges.

Power light indicating my 110 volt island of tools is alive.

The power cords are attached to wooden stakes which approach the ceiling. I'd have loved a totally "open concept" shop - but the center isles of machine tools had to have power drops. You always also need close work lights and tool racks - so you need support posts for same.

It was a big job pulling new lines of Romex into place. I snaked a pc. of 1" PVC back thru the ceiling towards the breaker box from the area I was targeting. I managed to push two lines of Romex thru it. One10 gauge for 220 and the 12 gauge for 110. I nearly succeeded. I crawled up the ladder for the 135 time, and peered into the insulation cloud of dust for the wires. There they were. They'd exited the PVC pipe - and one had gone atop another line of Romex and one had gone beneath. Thus - they were jammed and could be pulled no farther.

Of course! I'd expect no less. However; I chuckled ... "Is THAT all you got?" hahahaha

I took down the ceiling and sorted it all out. Found the insulation was jacked up from the help I'd briefly had doing a few odd jobs. I had to straighten out all that. Lovely stuff - fiberglass insulation.

Ceiling repaired along with insulation - in the studio kitchen ceiling and the main hall.

Ah the breaker box ... it looks soooooooo innocent just hanging there on the wall - doesn't it? Oh - the twists and turns that lurk within!

Progress. Much work. Much itching. A thousand trips up and 989 trips down the step ladder. I counted and I'm never wrong. And ... pretty mild pics as a result, for all the work. But - let's play this one again ...... hahaha.

And ... pretty mild pics as a result, for all the work. But - let's play this one again ...... hahaha.

Love it!

Gary

Edited 2 time(s). Last edit at 12/11/2012 02:03AM by barnespneumatic.

But I've done a bunch of wiring. Running 220 lines and 110 thru the walls, and ceiling. Fighting the 9 1/2" insulation blankets up there. They are marked R-30 so that's nice once you aren't handling them.

The Power light indicating I have 220 power to my big lathe. yeah.

The frame between the two larger lathes - which are back to back. This will hold work lights - and tool racks for the immediate tools being used for each job session. The coils of wire are for the ability to "roll out" the lathes for cleaning, etc. Both are on heavy wheeled carraiges.

Power light indicating my 110 volt island of tools is alive.

The power cords are attached to wooden stakes which approach the ceiling. I'd have loved a totally "open concept" shop - but the center isles of machine tools had to have power drops. You always also need close work lights and tool racks - so you need support posts for same.

It was a big job pulling new lines of Romex into place. I snaked a pc. of 1" PVC back thru the ceiling towards the breaker box from the area I was targeting. I managed to push two lines of Romex thru it. One10 gauge for 220 and the 12 gauge for 110. I nearly succeeded. I crawled up the ladder for the 135 time, and peered into the insulation cloud of dust for the wires. There they were. They'd exited the PVC pipe - and one had gone atop another line of Romex and one had gone beneath. Thus - they were jammed and could be pulled no farther.

Of course! I'd expect no less. However; I chuckled ... "Is THAT all you got?" hahahaha

I took down the ceiling and sorted it all out. Found the insulation was jacked up from the help I'd briefly had doing a few odd jobs. I had to straighten out all that. Lovely stuff - fiberglass insulation.

Ceiling repaired along with insulation - in the studio kitchen ceiling and the main hall.

Ah the breaker box ... it looks soooooooo innocent just hanging there on the wall - doesn't it? Oh - the twists and turns that lurk within!

Progress. Much work. Much itching. A thousand trips up and 989 trips down the step ladder. I counted and I'm never wrong.

And ... pretty mild pics as a result, for all the work. But - let's play this one again ...... hahaha.

And ... pretty mild pics as a result, for all the work. But - let's play this one again ...... hahaha.

Love it!

Gary

Edited 2 time(s). Last edit at 12/11/2012 02:03AM by barnespneumatic.

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 02:17AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

BTW - that center white frame between the two big lathes is mounted ON the carriage of the big lathe. It moves with the carriage. The other 110V stalk is mounted on the 110 Island of tools. Neither are mounted to the building. Thus the shock mount of a coil of romex in order to make adjusted movements of the tools, if needed.

The 220 V stalk shows another coil with a red cap. That will accept the box for the second 220V lathe - have to buy the fitting, or bring it next trip. The big surface grinder has it's Phase Generator still in Md. Should I need it sooner - I could buy a Phase Converter. But - that's not a high priority.

Oh ... the fan/light is down and the 4 tube T-8 flourescent unit is up. And, the moldings are down in the galley kitchen and mess off the floors.

Now, it will be back to putting stuff into place and organizing. The wood shop is functional, and that has really been handy. When I get this clutter sorted and my completed wrapped gun parts housed ... I'll have a pretty functional main machine shop here. After that - it's Range/Casting/HP Fill center Shak, Range lanes and backer .... then, later ... it will be the anodizing, bluing rooms, and the finishing booth. Tidy up Maryland ... and we're done. Simple. The welding/forging/iron shop will fill in between the cracks. That area will be for rougher work so the machines can be set around and used even if the environment isn't perfect. I've been taking things out of there to use and place elsewhere. Soon I will have enough room to place some of the stationary tools like the bandsaws, welders, and sanding lathe. I don't plan to have everything all polished before I feel I've completed the move.

And you thought it was gonna be a lot of work ...

Gary

Edited 1 time(s). Last edit at 12/11/2012 05:12AM by barnespneumatic.

The 220 V stalk shows another coil with a red cap. That will accept the box for the second 220V lathe - have to buy the fitting, or bring it next trip. The big surface grinder has it's Phase Generator still in Md. Should I need it sooner - I could buy a Phase Converter. But - that's not a high priority.

Oh ... the fan/light is down and the 4 tube T-8 flourescent unit is up. And, the moldings are down in the galley kitchen and mess off the floors.

Now, it will be back to putting stuff into place and organizing. The wood shop is functional, and that has really been handy. When I get this clutter sorted and my completed wrapped gun parts housed ... I'll have a pretty functional main machine shop here. After that - it's Range/Casting/HP Fill center Shak, Range lanes and backer .... then, later ... it will be the anodizing, bluing rooms, and the finishing booth. Tidy up Maryland ... and we're done. Simple. The welding/forging/iron shop will fill in between the cracks. That area will be for rougher work so the machines can be set around and used even if the environment isn't perfect. I've been taking things out of there to use and place elsewhere. Soon I will have enough room to place some of the stationary tools like the bandsaws, welders, and sanding lathe. I don't plan to have everything all polished before I feel I've completed the move.

And you thought it was gonna be a lot of work ...

Gary

Edited 1 time(s). Last edit at 12/11/2012 05:12AM by barnespneumatic.

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 02:41AM |

Registered: 15 years ago Posts: 234 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 05:14AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 05:19AM |

|

Registered: 15 years ago Posts: 122 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 02:34PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 02:39PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 03:43PM |

Registered: 13 years ago Posts: 780 |

Hi Gary,

Those pictures are showing the result of a lot of work invested. The shop keeps getting better every day. In my opinion, there’s still too much room available…

Common, don’t you quit on me, 11 more and you’ll get to a 1,000… For sure you are having stronger legs after this step ladder’s work out.

For sure you are having stronger legs after this step ladder’s work out.

Julio

Edited 1 time(s). Last edit at 12/11/2012 03:44PM by Julio.

Those pictures are showing the result of a lot of work invested. The shop keeps getting better every day. In my opinion, there’s still too much room available…

Common, don’t you quit on me, 11 more and you’ll get to a 1,000…

For sure you are having stronger legs after this step ladder’s work out.

For sure you are having stronger legs after this step ladder’s work out.

Julio

Edited 1 time(s). Last edit at 12/11/2012 03:44PM by Julio.

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 08:23PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 09:57PM |

Registered: 12 years ago Posts: 2,189 |

hey I'm thinking at least 2 or 3 employees to to man up that whole shop you got there because you know if those machines aint turning your not earnin

Hey my saw guy made this elf out of schedule 40 8 inch pipe and some angle iron found laying in the scrap gong the man has vision. Well let me know when I can mail you my resume

Thanks

Kurt

Hey my saw guy made this elf out of schedule 40 8 inch pipe and some angle iron found laying in the scrap gong the man has vision. Well let me know when I can mail you my resume

Thanks

Kurt

|

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 10:11PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Kurt,

Well, I think I can use your saw guy. hahahah

Yeah - if it were 1930 here, I could give some people work, and housing. But now, I'd have to pay them twice what I make, and pay insurance, bonding, lawyers, health bene's, 401k, and none of my facilities would be fit to house chickens. Therefore; I am I rock - I am an Island ...

Nice elf. You should give the guy a promotion, and then fire him for screwing around on company time! Merry Christmas!!

This is also humor - don't try this at home ...

Well, I think I can use your saw guy. hahahah

Yeah - if it were 1930 here, I could give some people work, and housing. But now, I'd have to pay them twice what I make, and pay insurance, bonding, lawyers, health bene's, 401k, and none of my facilities would be fit to house chickens. Therefore; I am I rock - I am an Island ...

Nice elf. You should give the guy a promotion, and then fire him for screwing around on company time! Merry Christmas!!

This is also humor - don't try this at home ...

|

Anonymous User

Re: Progress in Studio Shop NOW WITH PICS! December 11, 2012 11:41PM |

|

Re: Progress in Studio Shop NOW WITH PICS! December 12, 2012 12:42AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 12, 2012 03:52PM |

Registered: 13 years ago Posts: 780 |

|

Re: Progress in Studio Shop NOW WITH PICS! December 12, 2012 06:02PM |

Registered: 15 years ago Posts: 2,524 |

Nice work with the shop there, Gary. Although it's a bit anticlimactic to do all that work just to see a small green light silently illuminate, anyone who has done electrical work knows what you've been through to get there. And the best part is that since you've done it right, you probably won't have to touch it again for decades, if ever.

Unlike plumbing, which needs re-fixing on a regular basis. Especially when the former owners NEVER did things the right way.

Unlike plumbing, which needs re-fixing on a regular basis. Especially when the former owners NEVER did things the right way.

|

Re: Progress in Studio Shop NOW WITH PICS! December 12, 2012 06:08PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Sorry, only registered users may post in this forum.

Online Users

Guests:

12

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021