Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: The Cost of Custom

|

The Cost of Custom July 12, 2014 03:12PM |

|

Registered: 14 years ago Posts: 1,097 |

I didn't want to hijack Gary's topic thread in the other post, so thought I would start a new one.

Custom anything in today's market is through the roof in many areas. All the custom car shows, shops building custom, restored cars with budgets of $30 to $60K and even some that are $100K. I couldn't believe one episode. They upgrade a 1968 Ford F100. New front suspension, brakes, engine. They pressure washed the truck body, re-assembled truck body, and lightly sanded for a clear coat. They did not fix rust or damage body parts. Was to be a "Shop truck". They turn around and sell the truck for $28,000!!! I have rebuilt a truck in my late teens, it takes a lot of cash and I didn't even do a complete rebuild. But think about the hours spent, cost of new parts and a simple upgrade with new engine etc, it is $15,000 without any real body work. (That is if you get it done at at shop, less doing it yourself.)

My brother did body/paint for years. I told him a coworker wants his truck painted, but it is in pieces. Brother said he wouldn't even touch it for $12,000. He said it is to much work.

Back to custom parts.

A little story...

I finally took the time to go introduce myself to a local machining shop this week. While waiting to meet the owner, owner's son was speaking with a customer. The customer wanted 3 parts custom made, flat steel with a bend and 3 mounting holes, 2 x 3" with contours. Son said maybe $50 each. Customer, can you do it for $40? Son said, you can speak with my dad. The dad/owner came. "Hmmm that will take about 1 to 1.5 hrs to make so $90 or more." The customer - how come so much, I can order them from Honda cheaper. Owner said, " Well my cost is over $90". So customer left.

When I spoke with the owner, He said he gets that so often. I told him, that most people haven't made items themselves and have no idea what it actually takes to make even a simple bracket. He agreed. Anyway, I have a good source locally for materials.

I have not built any rifles to sell (yet). I do get emails asking for a price. So I tell them, I would want X amount. Next I tell them, you can buy a production Airforce Condor with accessories for less.You decide. The response, some have commented that a custom rifle should be cheaper for whatever reason. But I am not going to spend the 90 to 120 hours for free, sorry. Even building in bulk is a lot of hours.

So when Gary posts the steel work, I have to appreciate that getting to that stage is (guessing) 60 to 80 hours? Custom machining is a lot of setups even if you have a lot of tooling. I can imagine with engraving,etc, Gary might be more at 120+ hours?

I bought 9 items this past week, 4 reamers, 5 small endmills, that was $213! It takes much more tooling for manual machining than CNC. But CNC has huge initial cost, software that always has to he updated. Most software starting at $6000. So all in all custom is expensive. But that is what the end customer is paying for.

Anyway, sister-in-law and nephew here soon. He is helping with mowing today and yard work. I am still suppose to take it "easy" from surgery but feeling fine.

Have a good weekend.

Pedro

Custom anything in today's market is through the roof in many areas. All the custom car shows, shops building custom, restored cars with budgets of $30 to $60K and even some that are $100K. I couldn't believe one episode. They upgrade a 1968 Ford F100. New front suspension, brakes, engine. They pressure washed the truck body, re-assembled truck body, and lightly sanded for a clear coat. They did not fix rust or damage body parts. Was to be a "Shop truck". They turn around and sell the truck for $28,000!!! I have rebuilt a truck in my late teens, it takes a lot of cash and I didn't even do a complete rebuild. But think about the hours spent, cost of new parts and a simple upgrade with new engine etc, it is $15,000 without any real body work. (That is if you get it done at at shop, less doing it yourself.)

My brother did body/paint for years. I told him a coworker wants his truck painted, but it is in pieces. Brother said he wouldn't even touch it for $12,000. He said it is to much work.

Back to custom parts.

A little story...

I finally took the time to go introduce myself to a local machining shop this week. While waiting to meet the owner, owner's son was speaking with a customer. The customer wanted 3 parts custom made, flat steel with a bend and 3 mounting holes, 2 x 3" with contours. Son said maybe $50 each. Customer, can you do it for $40? Son said, you can speak with my dad. The dad/owner came. "Hmmm that will take about 1 to 1.5 hrs to make so $90 or more." The customer - how come so much, I can order them from Honda cheaper. Owner said, " Well my cost is over $90". So customer left.

When I spoke with the owner, He said he gets that so often. I told him, that most people haven't made items themselves and have no idea what it actually takes to make even a simple bracket. He agreed. Anyway, I have a good source locally for materials.

I have not built any rifles to sell (yet). I do get emails asking for a price. So I tell them, I would want X amount. Next I tell them, you can buy a production Airforce Condor with accessories for less.You decide. The response, some have commented that a custom rifle should be cheaper for whatever reason. But I am not going to spend the 90 to 120 hours for free, sorry. Even building in bulk is a lot of hours.

So when Gary posts the steel work, I have to appreciate that getting to that stage is (guessing) 60 to 80 hours? Custom machining is a lot of setups even if you have a lot of tooling. I can imagine with engraving,etc, Gary might be more at 120+ hours?

I bought 9 items this past week, 4 reamers, 5 small endmills, that was $213! It takes much more tooling for manual machining than CNC. But CNC has huge initial cost, software that always has to he updated. Most software starting at $6000. So all in all custom is expensive. But that is what the end customer is paying for.

Anyway, sister-in-law and nephew here soon. He is helping with mowing today and yard work. I am still suppose to take it "easy" from surgery but feeling fine.

Have a good weekend.

Pedro

|

Re: The Cost of Custom July 12, 2014 04:30PM |

Registered: 11 years ago Posts: 235 |

|

Re: The Cost of Custom July 14, 2014 05:41PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Pedro,

I think the point which would surprise people the most, would be the sheer number of tools, bits, jigs, measuring devices, cutters, and drawings; which are required to make the product. I am not exaggerating when I tell you that I suspect I use more then a thousand items to make the simplest PCP. Take away any, and they have to be replaced.

Gary

I think the point which would surprise people the most, would be the sheer number of tools, bits, jigs, measuring devices, cutters, and drawings; which are required to make the product. I am not exaggerating when I tell you that I suspect I use more then a thousand items to make the simplest PCP. Take away any, and they have to be replaced.

Gary

|

Re: The Cost of Custom July 15, 2014 02:19AM |

|

Registered: 14 years ago Posts: 1,097 |

Gary,

I would expect you are correct. When using manual machines a lot more tooling is required. I have only bought a few tools so far and already into the $500 range. I cannot imagine what you have accumulated over the years and the price to replace all those.

Hope you are doing well.

Pedro

I would expect you are correct. When using manual machines a lot more tooling is required. I have only bought a few tools so far and already into the $500 range. I cannot imagine what you have accumulated over the years and the price to replace all those.

Hope you are doing well.

Pedro

|

Re: The Cost of Custom July 14, 2014 11:11PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: The Cost of Custom July 15, 2014 12:00PM |

Registered: 12 years ago Posts: 2,189 |

I have always loved custom parts ! There is always a chance to IMPROVE on origional and if that's the reason for customization , then it should cost more . Like someone said earlier I just don't think the common person realizes how much effort goes into even drilling a hole and tapping threads. I have threaded millions of holes and I'm amazed at Gary's anvil stop on one of my( his) custom knives. I've didn't even know they made tapes and drills that small !! A watch maker/ jewler friend of mine does all of my micro work at it never ceases to amaze me . Small or big , custom or proto type , they all cost big but the quality is always better. And I always charge MORE if the customer wants to help! Anybody else???

|

Re: The Cost of Custom July 16, 2014 05:01PM |

Registered: 15 years ago Posts: 184 |

I get the same thing when I spec out a project for someone, whether its a security service or creating a custom iPhone app. If you are an employee of a company they may pay you $20 per hour. If the company hires someone to do custom work which they can not do themselves, they want to pay $2.00 per hour. And the shock on their faces when you give them a quote and its more then a few $$. They expect 200 hours of custom work to cost them a few hundred $$, not a few thousand. I gave one gentleman a quote for custom software and he went off the deep end. Ranting that we didn't want to make any money, that doing the work for him would increase our company's reputation and earn us more money in the future, etc. He wanted us to do the work for free with a promise of a piece of the profits IF he made money. That was a waste of 10 hours preparing the proposal and slide show.

Keith

Keith

|

Re: The Cost of Custom July 17, 2014 10:47PM |

|

Registered: 14 years ago Posts: 1,097 |

|

Re: The Cost of Custom July 17, 2014 11:12PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: The Cost of Custom July 17, 2014 04:46AM |

Registered: 15 years ago Posts: 780 |

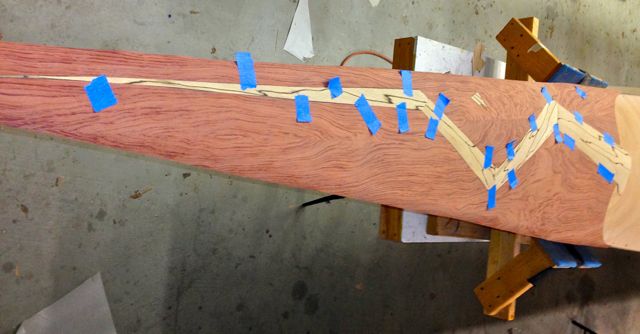

Working on some custom wood. Here is a tandem Kayak that I'm embellishing with some custom veneer. The theme is Thor's Hammer or Mjolner for those up on their Viking.

For those up on their woods the background is Bubinga and the bolt is Spalted maple.

I'll post Thor in his boat soon.

Kent

For those up on their woods the background is Bubinga and the bolt is Spalted maple.

I'll post Thor in his boat soon.

Kent

|

Re: The Cost of Custom July 17, 2014 02:51PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: The Cost of Custom July 17, 2014 10:48PM |

|

Registered: 14 years ago Posts: 1,097 |

|

Re: The Cost of Custom July 18, 2014 03:02AM |

Registered: 11 years ago Posts: 351 |

|

Re: The Cost of Custom July 18, 2014 04:52AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: The Cost of Custom July 29, 2014 01:23AM |

Registered: 15 years ago Posts: 2,524 |

Steel kayak, hmmm...

Betcha it could be done, but it would be as fragile as an empty beer can compared to a wooden one of equal weight. And then there's the rust issue, hmmm...no wonder they've stuck with wood for so long building small boats.

And the comment about tools and jigs got me wondering. If you put the basic lathe all by itself on one half of a balance scale, and then piled all the tooling; jigs, cutters, attachments, and measuring devices, etc. on the other side, which do you think would be the heavier? I'm guessing that the latter half exceeded the basic tool weight a bunch of years ago.

Edited 1 time(s). Last edit at 07/29/2014 01:31AM by rotorhead.

Betcha it could be done, but it would be as fragile as an empty beer can compared to a wooden one of equal weight. And then there's the rust issue, hmmm...no wonder they've stuck with wood for so long building small boats.

And the comment about tools and jigs got me wondering. If you put the basic lathe all by itself on one half of a balance scale, and then piled all the tooling; jigs, cutters, attachments, and measuring devices, etc. on the other side, which do you think would be the heavier? I'm guessing that the latter half exceeded the basic tool weight a bunch of years ago.

Edited 1 time(s). Last edit at 07/29/2014 01:31AM by rotorhead.

|

Re: The Cost of Custom July 29, 2014 09:24PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: The Cost of Custom July 29, 2014 10:09PM |

Registered: 15 years ago Posts: 2,524 |

Hello Jerry,

If you'll read my comment again, you'll notice that I didn't say equal strength, I said equal weight. Sure, steel is generally stronger than wood, but it's heavier too (though some species of wood are so dense that solid pieces won't actually float in water). For any given surface area to cover, the steel panel of equal weight to a wood one of equal size will be much thinner. While it would likely be stronger in ultimate yield strength, the thinner steel panel would likely be easily punctured in actual use where a certain amount of abuse is encountered when bouncing off stones and logs and such.

Given the generally stubborn nature of the human beast, I don't doubt that someone, somewhere, has built one out of steel just because they could.

If you'll read my comment again, you'll notice that I didn't say equal strength, I said equal weight. Sure, steel is generally stronger than wood, but it's heavier too (though some species of wood are so dense that solid pieces won't actually float in water). For any given surface area to cover, the steel panel of equal weight to a wood one of equal size will be much thinner. While it would likely be stronger in ultimate yield strength, the thinner steel panel would likely be easily punctured in actual use where a certain amount of abuse is encountered when bouncing off stones and logs and such.

Given the generally stubborn nature of the human beast, I don't doubt that someone, somewhere, has built one out of steel just because they could.

|

Re: The Cost of Custom July 30, 2014 03:13AM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: The Cost of Custom August 04, 2014 07:10AM |

Registered: 15 years ago Posts: 2,524 |

You're not kidding about those first generation fiberglass hulls being tough, there's still plenty of them up here working as commercial fishing boats. Some of them have been though dozens of owners, they're almost unbreakable. Back then the boat builders were just figuring out how to use that new-fangled resin and glass stuff. Like you said, they just laid up more and more layers until it "looked about right"...to a wooden boat builder with zero composite experience. They're WAY overbuilt, nearly solid glass, with no balsa wood inserts, no foam cores, no plywood buried between laminations, just lots and lots of fiberglass and resin. They're as heavy as battleships but nearly bulletproof, heck, some of them probably ARE bulletproof! A far cry from the legions of cruddy old Bayliners and Glastrons that you see abandoned in back yards and storage yards everywhere. Most of the light-but-cheap type fiberglass boats that followed have held up so poorly that you literally can't give them away. It seems that many of the surviving boat builders have finally figured out how to balance durability and light weight, but it's been pretty rough sailing getting to that point.

Sorry, only registered users may post in this forum.

Online Users

Guests:

24

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021