Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: How to

So anyways

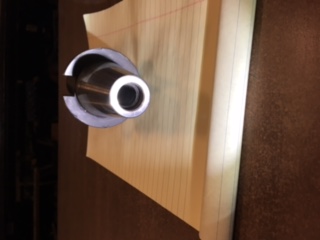

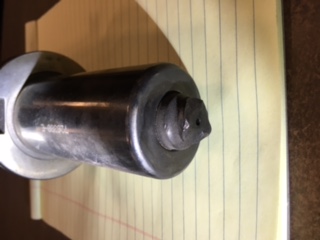

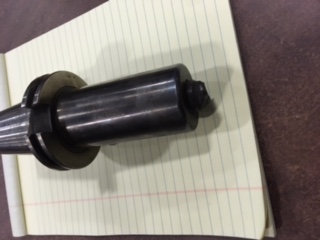

I've got these collets that have broken off Morse taper bits in them . They have a hole on the end for driving out drill bit no wedge hole in the side but the collet didn't have a key inside just a taper and I believe they spin welded inside together .

How can I get these out ? I've tried 100 ton press , I've tried heating up the outside not to cherry red but pretty hot . Next I guess I'll try to drill out Morse taper drill .

Has anyone ever had this problem ?

A new collet is over $1000

I've even tried welding a nut on the broken end of the drill bit and tried to wedge it out with a custom made fork !

Thanks

Kurt

Edited 1 time(s). Last edit at 05/09/2017 01:26PM by kurt wag.

I've got these collets that have broken off Morse taper bits in them . They have a hole on the end for driving out drill bit no wedge hole in the side but the collet didn't have a key inside just a taper and I believe they spin welded inside together .

How can I get these out ? I've tried 100 ton press , I've tried heating up the outside not to cherry red but pretty hot . Next I guess I'll try to drill out Morse taper drill .

Has anyone ever had this problem ?

A new collet is over $1000

I've even tried welding a nut on the broken end of the drill bit and tried to wedge it out with a custom made fork !

Thanks

Kurt

Edited 1 time(s). Last edit at 05/09/2017 01:26PM by kurt wag.

|

Re: How to May 09, 2017 02:30PM |

|

Registered: 12 years ago Posts: 326 |

Hi Kurt. when i have a broken stem in a watch crown... i use alum to rot the metal out.... of course these pieces are usually under a mm in size and it still takes hours. i wonder if it would work on your piece submerged in a hot alum solution to release the grip. Assuming the metal outside is less corrosive.

|

Re: How to May 09, 2017 03:20PM |

Registered: 8 years ago Posts: 208 |

Kurt,

This aluminum method watchman speaks of may be worth looking into.... if that doesn't work you may have to mill it out with a carbide end-mill.... this can be tricky/time consuming however.... you'll have to set it up in a vice tram it to dead center and carefully mill it... I would grind the surface of the broken bit flat first to give you minimal deflection then slowly peck your way in or write a pocket program on the mill if it has Cnc controls that way you can creep up on the overall I.D. Of the holder.... however if the broken bit is carbide this won't work!!! But from my experience I don't believe carbide can adhere to metals unless it's silver soldered ... so I'm guessing it's not carbide... prolly High speed steel m-42...... if all else fails water jet may do the trick...

Hope you get em back in working conditions those aren't cheap!!

Matt

This aluminum method watchman speaks of may be worth looking into.... if that doesn't work you may have to mill it out with a carbide end-mill.... this can be tricky/time consuming however.... you'll have to set it up in a vice tram it to dead center and carefully mill it... I would grind the surface of the broken bit flat first to give you minimal deflection then slowly peck your way in or write a pocket program on the mill if it has Cnc controls that way you can creep up on the overall I.D. Of the holder.... however if the broken bit is carbide this won't work!!! But from my experience I don't believe carbide can adhere to metals unless it's silver soldered ... so I'm guessing it's not carbide... prolly High speed steel m-42...... if all else fails water jet may do the trick...

Hope you get em back in working conditions those aren't cheap!!

Matt

|

Re: How to May 09, 2017 05:30PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

That's a shame Kurt.

I'd try soaking it overnight in WD40, then try your 100 ton press again.

I'm jealous of that 100 ton press! Whoooh.

I fear it spun gall burrs inside. Thus "keying" the parts together. Hate to think that, but your collet needs to be accurate. It's gonna be a challenge.

Thanks Kurt,

Great Post. Great comments Matt and Steve

Gary

I'd try soaking it overnight in WD40, then try your 100 ton press again.

I'm jealous of that 100 ton press! Whoooh.

I fear it spun gall burrs inside. Thus "keying" the parts together. Hate to think that, but your collet needs to be accurate. It's gonna be a challenge.

Thanks Kurt,

Great Post. Great comments Matt and Steve

Gary

|

Re: How to May 09, 2017 10:29PM |

Registered: 12 years ago Posts: 2,189 |

Hey guys

Thanks for the help .

Steve I've never heard of the warm alum before . Now we ARE talking about the spice right ? As a kid my mom would make us go out and pick grape leaves to put in the canning jars and she would say that they would help the alum keep the veggies / pickles crisp .

I'm excited to try it with maybe a duct tape funnel to direct it onto the drill directly .

Matt

I sure wish I had a mill . I know what you mean about little pockets and mill to exact tram . The drill bit isn't very hard . It's truly a holder that has a carbide or cobalt insert that does the actual cutting . It is fluted and has a hole down the center for coolant . It's very small maybe .062 . I do have a large old Cincinnati/ bickford drill press that I was going to try and drill down the center & then cave it in on itself . Thanks for the tip . I for sure will grind a good flat on it first .

Gary

Ah the 100 ton press . I tried welding the nut on first & wedging with a pickle fork but I hardened it in the process and it broke . Then I went to the press . It's an old Scotchman and I gave it all I could . I had it lined up and even made a shield to protect myself . I'm scared of the big tonnage and when the machine was grunting I wanted to reach in and smack the side a little to give it a shock .... but it wouldn't budge . I love pb blaster but I really don't think soaking it would help .

The first one I got stuck about a year ago and just threw into tool box till later . The other day I put the wrong length in the parameters ( tired and working too much ) and smashed her right into the material . I did salvage the end of the holder and install a new carbide but now it has a little wobble . So 2 collets out and I gotta fix em or replace em . These are ISO 45 holders . And not really easy to come by .

I'll keep y'all posted

Thanks

Kurt

Thanks for the help .

Steve I've never heard of the warm alum before . Now we ARE talking about the spice right ? As a kid my mom would make us go out and pick grape leaves to put in the canning jars and she would say that they would help the alum keep the veggies / pickles crisp .

I'm excited to try it with maybe a duct tape funnel to direct it onto the drill directly .

Matt

I sure wish I had a mill . I know what you mean about little pockets and mill to exact tram . The drill bit isn't very hard . It's truly a holder that has a carbide or cobalt insert that does the actual cutting . It is fluted and has a hole down the center for coolant . It's very small maybe .062 . I do have a large old Cincinnati/ bickford drill press that I was going to try and drill down the center & then cave it in on itself . Thanks for the tip . I for sure will grind a good flat on it first .

Gary

Ah the 100 ton press . I tried welding the nut on first & wedging with a pickle fork but I hardened it in the process and it broke . Then I went to the press . It's an old Scotchman and I gave it all I could . I had it lined up and even made a shield to protect myself . I'm scared of the big tonnage and when the machine was grunting I wanted to reach in and smack the side a little to give it a shock .... but it wouldn't budge . I love pb blaster but I really don't think soaking it would help .

The first one I got stuck about a year ago and just threw into tool box till later . The other day I put the wrong length in the parameters ( tired and working too much ) and smashed her right into the material . I did salvage the end of the holder and install a new carbide but now it has a little wobble . So 2 collets out and I gotta fix em or replace em . These are ISO 45 holders . And not really easy to come by .

I'll keep y'all posted

Thanks

Kurt

|

Re: How to May 10, 2017 02:55AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Well Kurt .....

The Straw hat tip guy AND the Thumbs up BOTH DUMP long posts. Drat!

Highlights:

Lathe drill interior stub to .025" wall. Keep about a 1/2" solid bottom to the bore. Soak. Then Press.

Yes. Inside a pipe cage with a plate steel welded foot.

Last idea:

Pipe cage with retaining plate steel washer foot (pipe diameter). So the whole mess can go into a heavy bench vise, the collet can slip inside, and if we are lucky, the stub can punch out.

Now; freeze the collet and stub. Have punch and 4 pound hammer ready with heavy glove.

Have second person with rosebud torch.

As quickly as possible - remove collet from freezer, have second man play torch over the collet for 20-30 seconds. Slide into cage. Apply punch and wrap punch strongly with 4 pound hammer. If the timing is right, it might snap the bond between warming collet and frozen stub.

Gary

The Straw hat tip guy AND the Thumbs up BOTH DUMP long posts. Drat!

Highlights:

Lathe drill interior stub to .025" wall. Keep about a 1/2" solid bottom to the bore. Soak. Then Press.

Yes. Inside a pipe cage with a plate steel welded foot.

Last idea:

Pipe cage with retaining plate steel washer foot (pipe diameter). So the whole mess can go into a heavy bench vise, the collet can slip inside, and if we are lucky, the stub can punch out.

Now; freeze the collet and stub. Have punch and 4 pound hammer ready with heavy glove.

Have second person with rosebud torch.

As quickly as possible - remove collet from freezer, have second man play torch over the collet for 20-30 seconds. Slide into cage. Apply punch and wrap punch strongly with 4 pound hammer. If the timing is right, it might snap the bond between warming collet and frozen stub.

Gary

|

Re: How to May 10, 2017 01:16AM |

|

Registered: 12 years ago Posts: 326 |

Hi Kurt, Yes the spice alum. I use it to remove broken screws in watch plates and also Rolex recommends using for removing a steel staff from a beryllium balance wheel. I have coated some parts with fingernail polish or a wax if i was unsure of the effect on the main piece i was trying to save from the corrosive process. These are tiny parts but maybe some form of the idea will work for you. Oh, and i'll use heat and an ultrasonic tank to speed up the process.

Steve

Steve

|

Re: How to May 11, 2017 10:10AM |

Registered: 12 years ago Posts: 2,189 |

Guy's

Thanks for all the great advise . Now I just have to find time to get on it . I really love the alum idea and will for sure try it first . I really believe it will take more than that but you just never know . The freezer method I've used for install bearings and it works great . I even thought liquid nitrogen and shatter it but hey they don't sell that at Wally World but I'm sure they got alum !

I'll let you know how it turned out . Thanks again . I've often checked the practical machinest site and got a few ideas on other problems.

Thanks

Kurt

Thanks for all the great advise . Now I just have to find time to get on it . I really love the alum idea and will for sure try it first . I really believe it will take more than that but you just never know . The freezer method I've used for install bearings and it works great . I even thought liquid nitrogen and shatter it but hey they don't sell that at Wally World but I'm sure they got alum !

I'll let you know how it turned out . Thanks again . I've often checked the practical machinest site and got a few ideas on other problems.

Thanks

Kurt

Sorry, only registered users may post in this forum.

Online Users

Guests:

33

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021