Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: Planned Obsolescence? Hah.

Planned Obsolescence? Hah.  September 09, 2020 09:51PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

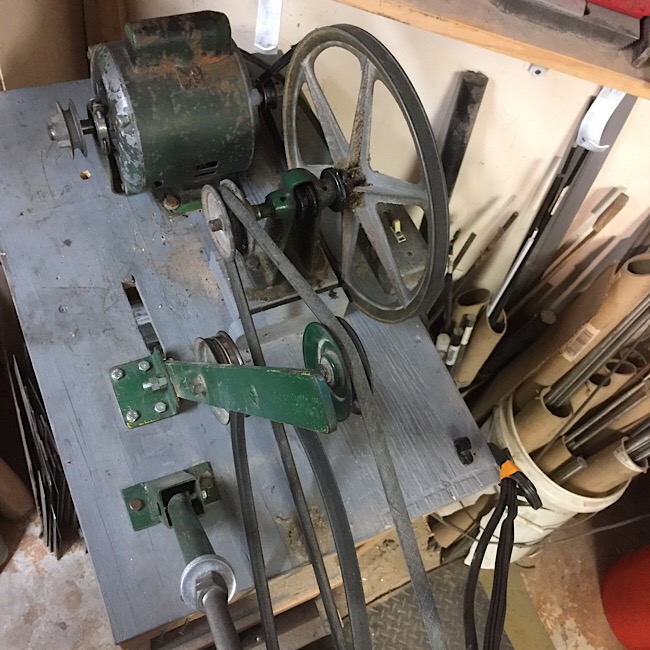

I’ve built quite a few of my tools. Various Belt Grinders. A 20 ton press. Rifling Bench. A 50 ton press. A Rolling Mill. Forges. A Power Hammer. Band Saw Transmissions. Buffers. Endless Dies and Jigs. Much more. I’m sure that you’d NEVER believe that after a mere 46 years, various items have demanded to be rebuilt ... all at once???? Did a timer go off??? Good grief. Bearings, tracking mechanisms, pulleys, motors. In fairness, the stuff I made from hardware store parts and raw plate and shaft have outlasted the commercial stuff! Ha. But I’ve been buried up to my greasy elbows for about two weeks.

And of course, things are different then they were. In the past, when a motor gave up ( and a new one was expensive - relative term - I’d buy a dual shaft bench grinder. Oddly they used to be about 1/2 to 1/3 the cost of just the raw motor. BUT, they stopped making “Capacitor Start” grinders. So they want to Oooooo...oooooooouuuzzzzz up to speed now where they used to just SNAP to life. That difference means they have no power to do anything until they wind up. So you can’t start a geared down Band Saw Transmission. They just sit and Hhhhhhhuuuuuuuummmmmmmmzzzz ... and remain at an evil sounding stand still. Don’t ask me how I know ...

And most cheaper of the expensive motors are single shaft. I used two to design my drive system for BOTH cutting Steel and Wood.

Now, what I WOULD HAVE told “Acquisition” to secure would have been a 56 Frame Double Shaft 3/4 horse power Capacitor Start Ball bearing 110 volt motor. But for a young fella like me, just starting out ... that was above my pay grade. The grinder I bought does make a lovely hummmmmmmmm. No, I won’t take it back. I took off the stones and shields until it weighs about as much as a 1/4” drill (hah), and that hummmmmmmmmmm probably isn’t great for it.

When

So I looked thru my bone yard. On shelves. Thought. And, one night at 3:30am, my brain tapped me. “What about your original forge blower you made up in 1980?” I said ... “do you realize it’s 3:30 am .... and what abou....”. “Huh. What motor did I put on that ....?” “Huh”. Maybe ...

In the morning I dug out the blower frame from the back left hand corner of the lower shop where it’s sat in a pallet since it was on the first pallet of still placed into that bay by the tractor unloading the trailer. It looks ROUGH ... but it is a 56, Capacitor Start, 1/2 horse, sleeve bearing, 110v. That’ll work. Dig it out.

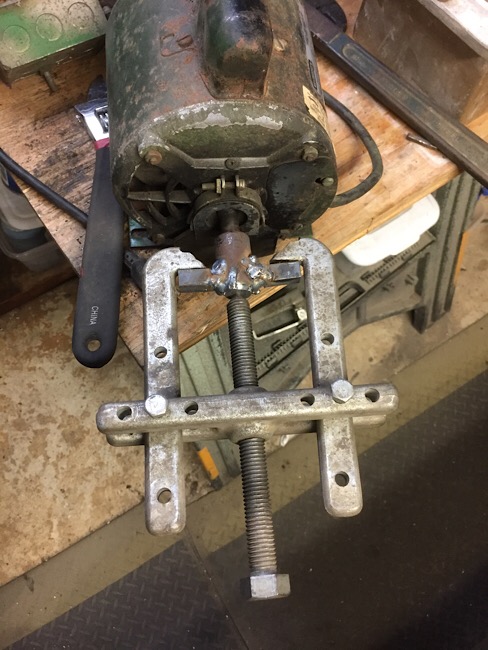

Well it had been adapted to run a flat belt on a 100 year old, cast Iron, dust system, factory blower weighing about 50 pounds. The flat pulley was NOT coming off.

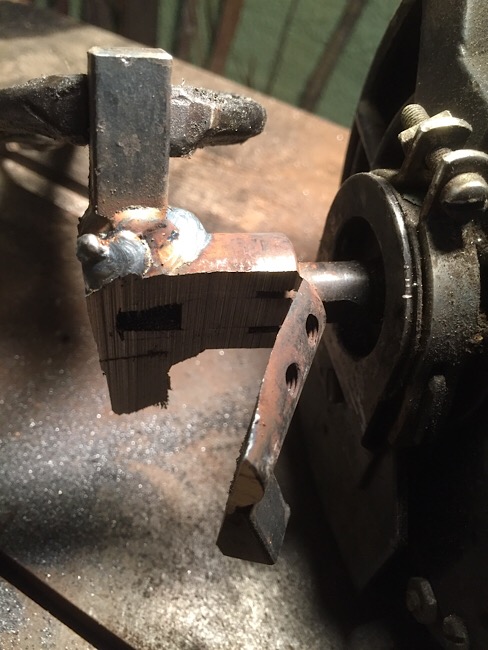

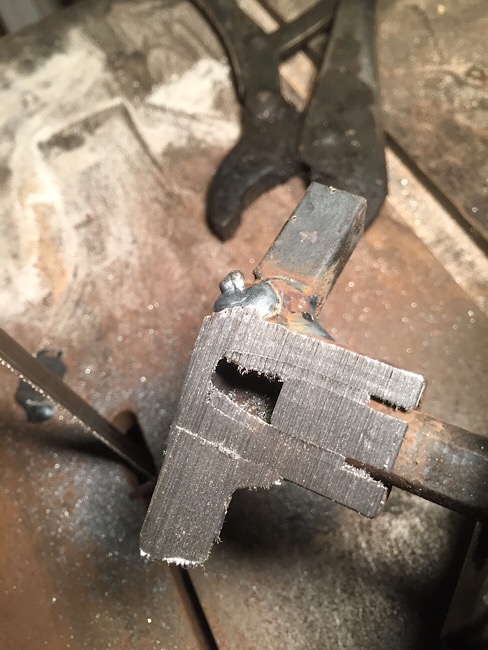

After I removed the flat pulley drum, I had to get the hub off. Yeah right! When any regular bite from a wheel puller did nothing. I decided to weld ears onto the hub. PULLLLLL!!!!! Nothing.

Ok. I’m done playing ...,

Still wouldn’t budge.

Stilll not. Of course after each cut I’m convinced it will now come off so I lock up the lower shop and return to the saw, carrying the motor to the upper shop.

Again ... Hey ... these things just FALL OFF!!!!

And it’s all reassembled. Simple. Throw the switch and it comes on. Both Steel and Wood Speeds are smooth. Looks like it was on the Ark. But it works great.

So I put away the 40% of my tools I’d had out for this simple job. And since I haven’t posted in a bit. I have now. These have been exceptionally painful weeks. Back, Neck. Just saying. So I’m trying to get the Shop Life back to a better level. I just had a dish of Kelly’s bread Pudding while doing this. I’m blessed. I’ll do my best now.

Gary

Edited 1 time(s). Last edit at 09/09/2020 10:03PM by barnespneumatic.

And of course, things are different then they were. In the past, when a motor gave up ( and a new one was expensive - relative term - I’d buy a dual shaft bench grinder. Oddly they used to be about 1/2 to 1/3 the cost of just the raw motor. BUT, they stopped making “Capacitor Start” grinders. So they want to Oooooo...oooooooouuuzzzzz up to speed now where they used to just SNAP to life. That difference means they have no power to do anything until they wind up. So you can’t start a geared down Band Saw Transmission. They just sit and Hhhhhhhuuuuuuuummmmmmmmzzzz ... and remain at an evil sounding stand still. Don’t ask me how I know ...

And most cheaper of the expensive motors are single shaft. I used two to design my drive system for BOTH cutting Steel and Wood.

Now, what I WOULD HAVE told “Acquisition” to secure would have been a 56 Frame Double Shaft 3/4 horse power Capacitor Start Ball bearing 110 volt motor. But for a young fella like me, just starting out ... that was above my pay grade. The grinder I bought does make a lovely hummmmmmmmm. No, I won’t take it back. I took off the stones and shields until it weighs about as much as a 1/4” drill (hah), and that hummmmmmmmmmm probably isn’t great for it.

When

So I looked thru my bone yard. On shelves. Thought. And, one night at 3:30am, my brain tapped me. “What about your original forge blower you made up in 1980?” I said ... “do you realize it’s 3:30 am .... and what abou....”. “Huh. What motor did I put on that ....?” “Huh”. Maybe ...

In the morning I dug out the blower frame from the back left hand corner of the lower shop where it’s sat in a pallet since it was on the first pallet of still placed into that bay by the tractor unloading the trailer. It looks ROUGH ... but it is a 56, Capacitor Start, 1/2 horse, sleeve bearing, 110v. That’ll work. Dig it out.

Well it had been adapted to run a flat belt on a 100 year old, cast Iron, dust system, factory blower weighing about 50 pounds. The flat pulley was NOT coming off.

After I removed the flat pulley drum, I had to get the hub off. Yeah right! When any regular bite from a wheel puller did nothing. I decided to weld ears onto the hub. PULLLLLL!!!!! Nothing.

Ok. I’m done playing ...,

Still wouldn’t budge.

Stilll not. Of course after each cut I’m convinced it will now come off so I lock up the lower shop and return to the saw, carrying the motor to the upper shop.

Again ... Hey ... these things just FALL OFF!!!!

And it’s all reassembled. Simple. Throw the switch and it comes on. Both Steel and Wood Speeds are smooth. Looks like it was on the Ark. But it works great.

So I put away the 40% of my tools I’d had out for this simple job. And since I haven’t posted in a bit. I have now. These have been exceptionally painful weeks. Back, Neck. Just saying. So I’m trying to get the Shop Life back to a better level. I just had a dish of Kelly’s bread Pudding while doing this. I’m blessed. I’ll do my best now.

Gary

Edited 1 time(s). Last edit at 09/09/2020 10:03PM by barnespneumatic.

Re: Planned Obsolescence? Hah.  September 10, 2020 01:04AM |

Registered: 15 years ago Posts: 573 |

Re: Planned Obsolescence? Hah.  September 10, 2020 01:58AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Scott,

Yes. Most things are”made disposable” these days. And the players just can’t understand why you aren’t always prepared for their “plug and play” solutions. Hey, it’s only $650. Or we can arrange for you to join our “pay forever”club. “Repair it???”, don’t be absurd. This isn’t 1980 or something - hahaaaaahahhhhh.

Always good to hear from you Scott

Gary

Yes. Most things are”made disposable” these days. And the players just can’t understand why you aren’t always prepared for their “plug and play” solutions. Hey, it’s only $650. Or we can arrange for you to join our “pay forever”club. “Repair it???”, don’t be absurd. This isn’t 1980 or something - hahaaaaahahhhhh.

Always good to hear from you Scott

Gary

Re: Planned Obsolescence? Hah.  September 11, 2020 04:39PM |

Admin Registered: 15 years ago Posts: 1,489 |

Re: Planned Obsolescence? Hah.  September 14, 2020 03:23PM |

|

Registered: 14 years ago Posts: 1,097 |

Gary,

Good post. It is amazing how the old motors will last and last. Everything new is expensive and not built to last like those motors.

I bought a used 4" band saw a few years back. Motor was done, limping along. A new motor is $300+ for that saw, and a brand new saw is $500. Go figure, they want you to buy another saw rather than replace parts, the same route so many things are going.

I have been able to find used motors here and there, I have 1hp motor that will go on the saw eventually, overkill as original is 1/2hp but for $40 not an issue.

Recently our dryer was squealing. I took it all apart and found that the drum rollers had no grease left. Not only that, its steel bushing on steel shafts. Another smart "engineer" out there. Should be brass sleeves or bearings. Bearings are cheap these days and a big company like LG can easily incorporate bearing into their design, at least you would think. But they want to you replace all appliances every 8-10 years so they can make more profit. Just how it has become.

Thanks for sharing, I hope you are able to keep working through the pains.

Pedro

Good post. It is amazing how the old motors will last and last. Everything new is expensive and not built to last like those motors.

I bought a used 4" band saw a few years back. Motor was done, limping along. A new motor is $300+ for that saw, and a brand new saw is $500. Go figure, they want you to buy another saw rather than replace parts, the same route so many things are going.

I have been able to find used motors here and there, I have 1hp motor that will go on the saw eventually, overkill as original is 1/2hp but for $40 not an issue.

Recently our dryer was squealing. I took it all apart and found that the drum rollers had no grease left. Not only that, its steel bushing on steel shafts. Another smart "engineer" out there. Should be brass sleeves or bearings. Bearings are cheap these days and a big company like LG can easily incorporate bearing into their design, at least you would think. But they want to you replace all appliances every 8-10 years so they can make more profit. Just how it has become.

Thanks for sharing, I hope you are able to keep working through the pains.

Pedro

Re: Planned Obsolescence? Hah.  September 16, 2020 03:01PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Pedro,

You are right on all.

New 4 1/2” horizontal Band Saw from Harbor Freight is $225. I have two of them. They work great.

I bought a 1 1/2 hp electric motor at a salvage yard about 45 years ago. $10. It weighs about sixty pounds. Has Oiler ports each end of shaft. Will most likely last forever. In an early shop about 1978, I ran a line shaft with it and rigged about 5-6 tools to run from it. In removing it later, it slipped from my hands and fell about 9’ to concrete floor. It broke one cast iron end into a spider web pattern of maybe 6 pieces. I tapped all back into place. Gingerly carried it to the stick welder. Welded all the crack tracks. That was in 1979. It still runs perfectly. New things weigh less than the box they come in and have little staying power.

Ok. Wrist says that is enough typing

Gary

You are right on all.

New 4 1/2” horizontal Band Saw from Harbor Freight is $225. I have two of them. They work great.

I bought a 1 1/2 hp electric motor at a salvage yard about 45 years ago. $10. It weighs about sixty pounds. Has Oiler ports each end of shaft. Will most likely last forever. In an early shop about 1978, I ran a line shaft with it and rigged about 5-6 tools to run from it. In removing it later, it slipped from my hands and fell about 9’ to concrete floor. It broke one cast iron end into a spider web pattern of maybe 6 pieces. I tapped all back into place. Gingerly carried it to the stick welder. Welded all the crack tracks. That was in 1979. It still runs perfectly. New things weigh less than the box they come in and have little staying power.

Ok. Wrist says that is enough typing

Gary

Re: Planned Obsolescence? Hah.  September 17, 2020 04:25PM |

Registered: 12 years ago Posts: 2,189 |

You all hit the nail in the head there . Even the industrial fans are crap now a days . Motors are small as your fist and not serviceable. I’ve got an old Patterson 4 pole fan that burned up . It’s got the oil weep holes front and back with bushings .

I won’t throw it out . It’s the perfect size all metal with a great blade. I watch the garbage on the road side for any old 4 pole fans that I could resurrect.

Thanks

Kurt

I won’t throw it out . It’s the perfect size all metal with a great blade. I watch the garbage on the road side for any old 4 pole fans that I could resurrect.

Thanks

Kurt

Sorry, only registered users may post in this forum.

Online Users

Guests:

18

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021