Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: Master Die complete and Pressed

|

Master Die complete and Pressed August 20, 2022 02:32PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

NOTE: If you posted on this thread ... please repeat. The Forum has a control called “Hide and Replies”. I can’t imagine why. Since I’m an Administrator, the button is active. A couple of times lately, I’ve touched it. First to see what controls and choices were available. NOTHING!. POOF ... the whole thread is gone. Gone where? Who knows??? How do you restore it? Who knows. I’ve looked everywhere. It’s maddening. This morning I was coming to see what may have been added to the forum. Before I even saw if there was anything added to my post from last night .... Poof!!!! I had accidentally brushed the HIDE button! Gone. Who thought this was a great idea???

Well, I’m adding back, as I can recall; what I posted last night. If you responded, please repeat.

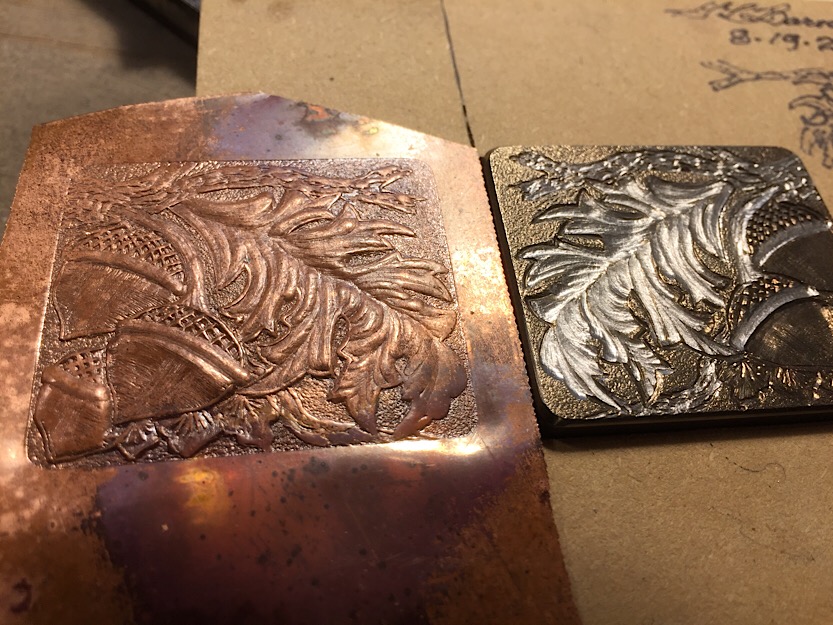

This is right off the press. No touch up. I like it. Comments?

We will have various options for Oak Leaves and Acorns. This is a “Gang Die” with all components on one block. Previously I made individual components. We will use both.

As I recall more I’ll post. Thanks for your cooperation!

Oh ... this Prototype Press is in Copper.

Gary

Well, I’m adding back, as I can recall; what I posted last night. If you responded, please repeat.

This is right off the press. No touch up. I like it. Comments?

We will have various options for Oak Leaves and Acorns. This is a “Gang Die” with all components on one block. Previously I made individual components. We will use both.

As I recall more I’ll post. Thanks for your cooperation!

Oh ... this Prototype Press is in Copper.

Gary

|

Re: Master Die complete and Pressed August 20, 2022 03:19PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Remember - this is a repeat due to an accidental delete. If you responded earlier ... please repeat your reply.

The pic above shown the copper first pressing. Fresh Press - no Tweaking details What does that mean? Sometimes unequal pressure on the die and metal will make a Print with lesser detail on one side than is actually cut into the die. IF YOU RE-Register the Metal and Die, you can get another press in. Remember ... I’m dealing with tiny tiny measurements. Consider ... the entire sheet of Copper is only 25 thousandths. Now think, all the detail has to be designed to be cut to less than approx. half that. Then I’m taking imprints with handmade machines and tools. When I cut the steel, it’s cut “Relative to” everything else on the panel. I must use the tools of “illusion, shadow, width of cut, depth of cut, and type of cut”. All designed to speak to your eye and share information: this is in front of that, this is primary, this is a secondary image. This is in focus - this just “suggested”. All done with details you cut into Tool Steel at a depth you just “sense.”

If you re-register a plate on the die to increase pressure in a certain area, it must line up perfectly and stay put while you work it. Otherwise you will ruin the whole work by over- printing an area.

Cite for example. This copper pressing. Right side. Last leaf on stem. You see it doesn’t have quite the detail of the leaf to it’s left? The detail is in the die. The polished leaf would blend, but I’ll most likely re-register it and force it deeper to accept more detail. Or ruin the whole panel!!!

Hope you enjoyed the info. And sorry I don’t know how to restore the hidden original message post and comments. In all these years that button hasn’t been a problem. Now it’s gotten bigger I guess. Haha

Edited 1 time(s). Last edit at 08/20/2022 03:24PM by barnespneumatic.

The pic above shown the copper first pressing. Fresh Press - no Tweaking details What does that mean? Sometimes unequal pressure on the die and metal will make a Print with lesser detail on one side than is actually cut into the die. IF YOU RE-Register the Metal and Die, you can get another press in. Remember ... I’m dealing with tiny tiny measurements. Consider ... the entire sheet of Copper is only 25 thousandths. Now think, all the detail has to be designed to be cut to less than approx. half that. Then I’m taking imprints with handmade machines and tools. When I cut the steel, it’s cut “Relative to” everything else on the panel. I must use the tools of “illusion, shadow, width of cut, depth of cut, and type of cut”. All designed to speak to your eye and share information: this is in front of that, this is primary, this is a secondary image. This is in focus - this just “suggested”. All done with details you cut into Tool Steel at a depth you just “sense.”

If you re-register a plate on the die to increase pressure in a certain area, it must line up perfectly and stay put while you work it. Otherwise you will ruin the whole work by over- printing an area.

Cite for example. This copper pressing. Right side. Last leaf on stem. You see it doesn’t have quite the detail of the leaf to it’s left? The detail is in the die. The polished leaf would blend, but I’ll most likely re-register it and force it deeper to accept more detail. Or ruin the whole panel!!!

Hope you enjoyed the info. And sorry I don’t know how to restore the hidden original message post and comments. In all these years that button hasn’t been a problem. Now it’s gotten bigger I guess. Haha

Edited 1 time(s). Last edit at 08/20/2022 03:24PM by barnespneumatic.

|

Re: Master Die complete and Pressed September 02, 2022 04:14AM |

|

Registered: 14 years ago Posts: 1,097 |

I remember seeing the details cut into the small oak leaf dies you working working on back in May during my visit. This one is much more impressive due to its size! Most people would never understand that this is all hand engraved and not cut on a CNC mill from a digital model.

I am sure you had to work out the registering of the imprint. With so much detail it must take a lot of pressure to capture the image especially in the nickel metal.

Again, looking forward to seeing my case!

Pedro

I am sure you had to work out the registering of the imprint. With so much detail it must take a lot of pressure to capture the image especially in the nickel metal.

Again, looking forward to seeing my case!

Pedro

|

Re: Master Die complete and Pressed September 02, 2022 02:59PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Peter,

Thank you for your post. I know that you have considerable experience in programming for CNC machines. That gives you a special appreciation for the technology developed as an alternative to what came before.

Readers, please bear with me. I sincerely believe this is relevant and interesting. We’ve come to some interesting crossroads in our Society. Every society does. Consider the ..... ..... Crossbow. “Excuse me???” Yes ... “Crossbow”. Before the Crossbow, was the Longbow. It took quite a lot of practice to effectively shoot a Longbow. Especially a powerful one. It took strength, a keen eye, balance, and concentration. This boils down to “Talent”. It took time to develop an “Archer”. And an Archer was highly prized by the organizers of Armies. Imagine the effort required to field and entire Regiment of Archers. Perhaps two hundred skilled men. Robin Hood’s of type. It’s nearly impossible. But that is why there was endless efforts to develop the skill as children grew. It’s why there was Archery ranges on the Village Green and everyone was pressed to put in their hours of practice and strength training. If you pull an 80 pound war bow, you will know why!

Commanders developed ways to compensate for the inevitable lack of Robin Hood’s they had to go to war with. One such technique: a FLIGHT OF ARROWS. All your archers were directed to coordinate their fire. To lift their drawn bows skyward, aim at the enemy mass in general (across the field of battle), and release their arrows as one, on command. The Air would FILL with arrows. 200 arrows screaming at the enemy line - as one. They were going to hit SOMETHING! And they did. Such techniques were developed due to the lack of being able to train enough really skilled archers.

Someone thought, “What if we took several of the difficult skills of Archery, and built a machine to handle those.” How about a winch or lever to draw the bow - so we can use some of these skinny smaller guys. How about a clever multi-lever trigger assembly for a smooth release. How about a ridged frame to hold the bow drawn while aiming?!!! Hey, we could cut the training time by 10x. We could quickly teach an ordinary Joe to knock a skilled Knight off his steed!!! And ... they did!!!

How about skilled machinists? Easy to produce? No. It takes time. Takes a keen eye. Takes dexterity. How about skilled Engravers? No. Takes far more time and natural skills then the machinist. Can you draw? I mean, really really well? How many people can? Now, can you cut your drawing into steel??? Hey, this digital technology. Do you think we could program a precise milling machine to reproduce the work of a skilled engraver??? Hey .... mostly, yes!!! And we tried it, and it worked! It worked to the point where skilled programmers command far greater respect and reward than do skilled Engravers! The society changed. They became far less willing to give respect to the single skilled engraver. I mean, it’s not really fair... right. I mean, he started with natural skills. He could judge distance. He could draw for Heaven’s sake! He had patience. He could apply himself with concentration. We can’t all do that. We’d rather give praise to the winning Cage Fighter. Give obscene amounts of money to sport figures. And now, we’ve got these clever machines that can engrave - over and over again.

But; once in a while ... someone comes along. He has quite a few natural skills. He has an interest in traditional art forms. He has the determination, the patience, and concentration. He practices. He practices for decades. His work looks pretty good. Doesn’t work as fast as our CNC Mill. But ... should we give him respect? Always to be seen. Always depends upon the background of the person seeing his work.

I’ll be back Peter. Thank you, as a Programmer, for showing respect for this old Artist. Thank you my friend.

Gary

Thank you for your post. I know that you have considerable experience in programming for CNC machines. That gives you a special appreciation for the technology developed as an alternative to what came before.

Readers, please bear with me. I sincerely believe this is relevant and interesting. We’ve come to some interesting crossroads in our Society. Every society does. Consider the ..... ..... Crossbow. “Excuse me???” Yes ... “Crossbow”. Before the Crossbow, was the Longbow. It took quite a lot of practice to effectively shoot a Longbow. Especially a powerful one. It took strength, a keen eye, balance, and concentration. This boils down to “Talent”. It took time to develop an “Archer”. And an Archer was highly prized by the organizers of Armies. Imagine the effort required to field and entire Regiment of Archers. Perhaps two hundred skilled men. Robin Hood’s of type. It’s nearly impossible. But that is why there was endless efforts to develop the skill as children grew. It’s why there was Archery ranges on the Village Green and everyone was pressed to put in their hours of practice and strength training. If you pull an 80 pound war bow, you will know why!

Commanders developed ways to compensate for the inevitable lack of Robin Hood’s they had to go to war with. One such technique: a FLIGHT OF ARROWS. All your archers were directed to coordinate their fire. To lift their drawn bows skyward, aim at the enemy mass in general (across the field of battle), and release their arrows as one, on command. The Air would FILL with arrows. 200 arrows screaming at the enemy line - as one. They were going to hit SOMETHING! And they did. Such techniques were developed due to the lack of being able to train enough really skilled archers.

Someone thought, “What if we took several of the difficult skills of Archery, and built a machine to handle those.” How about a winch or lever to draw the bow - so we can use some of these skinny smaller guys. How about a clever multi-lever trigger assembly for a smooth release. How about a ridged frame to hold the bow drawn while aiming?!!! Hey, we could cut the training time by 10x. We could quickly teach an ordinary Joe to knock a skilled Knight off his steed!!! And ... they did!!!

How about skilled machinists? Easy to produce? No. It takes time. Takes a keen eye. Takes dexterity. How about skilled Engravers? No. Takes far more time and natural skills then the machinist. Can you draw? I mean, really really well? How many people can? Now, can you cut your drawing into steel??? Hey, this digital technology. Do you think we could program a precise milling machine to reproduce the work of a skilled engraver??? Hey .... mostly, yes!!! And we tried it, and it worked! It worked to the point where skilled programmers command far greater respect and reward than do skilled Engravers! The society changed. They became far less willing to give respect to the single skilled engraver. I mean, it’s not really fair... right. I mean, he started with natural skills. He could judge distance. He could draw for Heaven’s sake! He had patience. He could apply himself with concentration. We can’t all do that. We’d rather give praise to the winning Cage Fighter. Give obscene amounts of money to sport figures. And now, we’ve got these clever machines that can engrave - over and over again.

But; once in a while ... someone comes along. He has quite a few natural skills. He has an interest in traditional art forms. He has the determination, the patience, and concentration. He practices. He practices for decades. His work looks pretty good. Doesn’t work as fast as our CNC Mill. But ... should we give him respect? Always to be seen. Always depends upon the background of the person seeing his work.

I’ll be back Peter. Thank you, as a Programmer, for showing respect for this old Artist. Thank you my friend.

Gary

|

Re: Master Die complete and Pressed September 02, 2022 04:43PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I’m back

To make sure ... I’m not downing CNC. Or the Crossbow. Hah.

To be sure, you’d hardly want a factory full of “Artists” making your products. Heaven help us. They’d all be different. They’d be done as soon an the Artists could finish them ... time for each variable.

And the respect I speak of for the Artists are maybe better described as courtesy. When the format is set up and purchased to produce two way conversation, that would be a fun format. Because one Bear on a Unicycle can’t hold an audience forever. It’s friends sharing activities that produce some good stories, pictures, and a great forum.

You’ll never have to be bored with ...”Seen that before” ... “Another one of those” ... “Not that again ....”. As long as you drop by, you will see new things. Help fill in the gaps if you can please. Things happen. Like chemical erosion while removing oxide, which ruins parts ... for example. Yep. It happens.

Thanks for commenting.

Gary

To make sure ... I’m not downing CNC. Or the Crossbow. Hah.

To be sure, you’d hardly want a factory full of “Artists” making your products. Heaven help us. They’d all be different. They’d be done as soon an the Artists could finish them ... time for each variable.

And the respect I speak of for the Artists are maybe better described as courtesy. When the format is set up and purchased to produce two way conversation, that would be a fun format. Because one Bear on a Unicycle can’t hold an audience forever. It’s friends sharing activities that produce some good stories, pictures, and a great forum.

You’ll never have to be bored with ...”Seen that before” ... “Another one of those” ... “Not that again ....”. As long as you drop by, you will see new things. Help fill in the gaps if you can please. Things happen. Like chemical erosion while removing oxide, which ruins parts ... for example. Yep. It happens.

Thanks for commenting.

Gary

Sorry, only registered users may post in this forum.

Online Users

Guests:

32

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021