Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: 1st lathe project

|

1st lathe project September 25, 2010 11:29PM |

Admin Registered: 15 years ago Posts: 1,489 |

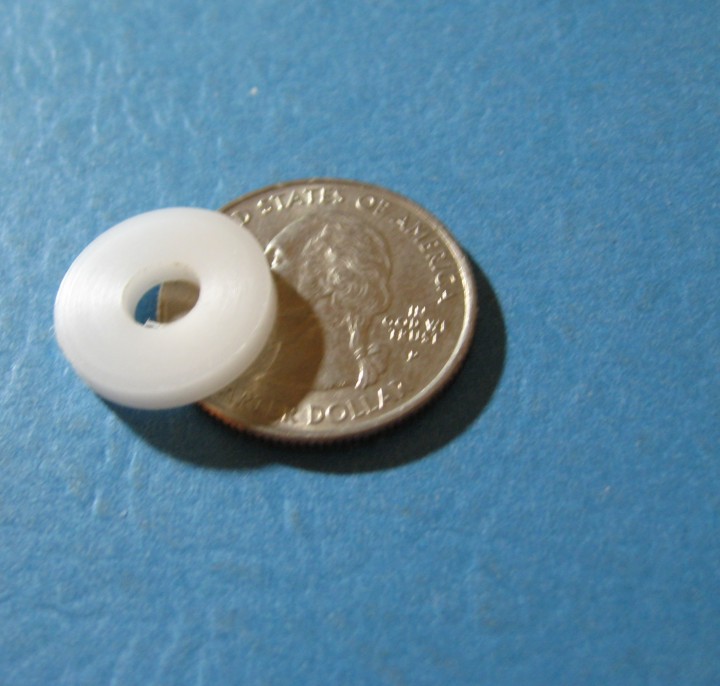

Everything in my apartment has to do double or triple duty. I bought some cheap grinding wheels from Harbor Freight in a variety of grits to grind and sharpen lathe bits and I needed to make some arbor/spacing disks so that the wheels spin as true as possible in the lathe when chucked. Since everybody has been emailing me incessantly about my lathe -  - to ask me what has become of it I thought I would post this.

- to ask me what has become of it I thought I would post this.

After trueing up the headstock chuck, installing a quick change toolpost and a quick release tailstock mod I completed the last setup trueing up the tailstock to the headstock, chucked up a piece of Delrin round stock and jumped right in, I needed 4.

This was an opportunity to practice with a productive project as opposed to just wasting material. It required drilling, turning, facing the next part and parting; all of the basic lathe operations.

I will be partnering with Gary to help with special high tech R&D machining so expect to see some amazing things coming out of the shop soon.

- to ask me what has become of it I thought I would post this.

- to ask me what has become of it I thought I would post this.

After trueing up the headstock chuck, installing a quick change toolpost and a quick release tailstock mod I completed the last setup trueing up the tailstock to the headstock, chucked up a piece of Delrin round stock and jumped right in, I needed 4.

This was an opportunity to practice with a productive project as opposed to just wasting material. It required drilling, turning, facing the next part and parting; all of the basic lathe operations.

I will be partnering with Gary to help with special high tech R&D machining so expect to see some amazing things coming out of the shop soon.

|

Re: 1st lathe project September 26, 2010 12:03AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: 1st lathe project September 26, 2010 01:27AM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: 1st lathe project September 26, 2010 02:24AM |

Registered: 13 years ago Posts: 780 |

|

Re: 1st lathe project September 26, 2010 02:53AM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: 1st lathe project September 27, 2010 11:53PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: 1st lathe project September 28, 2010 05:13AM |

Admin Registered: 15 years ago Posts: 1,489 |

Jerry,

Yes, basics.

It was quite a project just getting the lathe set up with the "necessary" mod's like the quick change tool post, quick release tailstock and getting it onto a rollaway cart before doing any projects. I've been working up to this day for many, many months.

I fooled around for hours just making a dozen of those arbor/mandrel spacers. They had to be "just so" ya understand. .

.

It was cool just firing it up in finished form without throwing the chuck key across the room after leaving it in the headstock by mistake and actually having a legitimate purpose.

My 2nd project is Crosman valve work.

Lon

Edited 1 time(s). Last edit at 09/28/2010 05:19AM by Bigbore.

Yes, basics.

It was quite a project just getting the lathe set up with the "necessary" mod's like the quick change tool post, quick release tailstock and getting it onto a rollaway cart before doing any projects. I've been working up to this day for many, many months.

I fooled around for hours just making a dozen of those arbor/mandrel spacers. They had to be "just so" ya understand.

.

.

It was cool just firing it up in finished form without throwing the chuck key across the room after leaving it in the headstock by mistake and actually having a legitimate purpose.

My 2nd project is Crosman valve work.

Lon

Edited 1 time(s). Last edit at 09/28/2010 05:19AM by Bigbore.

|

Re: 1st lathe project September 28, 2010 06:12AM |

Registered: 15 years ago Posts: 966 |

|

Re: 1st lathe project September 28, 2010 06:34PM |

Admin Registered: 15 years ago Posts: 1,489 |

|

Re: 1st lathe project September 28, 2010 06:43PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Lon,

Just a tip, if you'll allow. I think I understand that you plan to chuck up some grinding stones to sharpen lathe tools. Meaning, you chuck them in the lathe and grind there. Innovative thinking. However; consider that the worst thing you could ever do would be to get the sluffed off grinding stone particles anywhere near your lathe. Those particles will get everywhere. Stick to any oily surface. And, grind the heck out of your ways and any moving parts.

I may have misunderstood. If not, consider getting a cheap fifty dollar Harbor Freight grinder, and use the thing out on the balcony. Any grinding is a really filthy job ... and you really want a water drip on the tools to keep them from being burnt too.

Gary

Just a tip, if you'll allow. I think I understand that you plan to chuck up some grinding stones to sharpen lathe tools. Meaning, you chuck them in the lathe and grind there. Innovative thinking. However; consider that the worst thing you could ever do would be to get the sluffed off grinding stone particles anywhere near your lathe. Those particles will get everywhere. Stick to any oily surface. And, grind the heck out of your ways and any moving parts.

I may have misunderstood. If not, consider getting a cheap fifty dollar Harbor Freight grinder, and use the thing out on the balcony. Any grinding is a really filthy job ... and you really want a water drip on the tools to keep them from being burnt too.

Gary

|

Re: 1st lathe project September 29, 2010 05:13AM |

Admin Registered: 15 years ago Posts: 1,489 |

Gary,

You understood correctly, I planned to grind tool bits on the lathe. I was going to put tin foil down on everything before grinding to contain the the abrasive particles. No serious grinding, just a little practice. I've read about the water dip.

I only have $6 invested in the grinding wheels so it wouldn't be a huge loss to scrap the whole project so I'll reconsider based on your advice.

Lon

You understood correctly, I planned to grind tool bits on the lathe. I was going to put tin foil down on everything before grinding to contain the the abrasive particles. No serious grinding, just a little practice. I've read about the water dip.

I only have $6 invested in the grinding wheels so it wouldn't be a huge loss to scrap the whole project so I'll reconsider based on your advice.

Lon

|

Re: 1st lathe project September 29, 2010 03:12PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Lon,

It can be done, but I think you'd find it to be a pain. I do have one small lathe that I "die grind" on. But - I've given it over to that operation, and have no illusions about it's future. You'll be amazed at how much grit and ground steel is produced. And, when mixed with water, it forms a paste that sticks like glue to everything. If it gets between the carriage and the ways, it will just grind away your lathe bed. In addition, unless your wheel is enclosed back and top, you will have an exceptional rooster tail of filth on wall and ceiling.

It's been my expoerience that "multi-use" tools are a required evil - to be avoided if at all possible. In this instance, when small grinders are so relatively cheap - I think you might avoid the issues this time.

Glad you are enjoying your tooling. Please share more. Perhaps you can produce some Kennedy halves next time ... hehehe.

Perhaps you can produce some Kennedy halves next time ... hehehe.

Gary

It can be done, but I think you'd find it to be a pain. I do have one small lathe that I "die grind" on. But - I've given it over to that operation, and have no illusions about it's future. You'll be amazed at how much grit and ground steel is produced. And, when mixed with water, it forms a paste that sticks like glue to everything. If it gets between the carriage and the ways, it will just grind away your lathe bed. In addition, unless your wheel is enclosed back and top, you will have an exceptional rooster tail of filth on wall and ceiling.

It's been my expoerience that "multi-use" tools are a required evil - to be avoided if at all possible. In this instance, when small grinders are so relatively cheap - I think you might avoid the issues this time.

Glad you are enjoying your tooling. Please share more.

Perhaps you can produce some Kennedy halves next time ... hehehe.

Perhaps you can produce some Kennedy halves next time ... hehehe.

Gary

|

Re: 1st lathe project September 29, 2010 03:15PM |

Registered: 15 years ago Posts: 438 |

Sorry, only registered users may post in this forum.

Online Users

Guests:

25

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021