Home

>

Airgun Rendezvous Main Forum

>

Topic

Re: Lathe Progress

Lathe Progress FINAL PICS ADDED  June 13, 2010 04:14PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

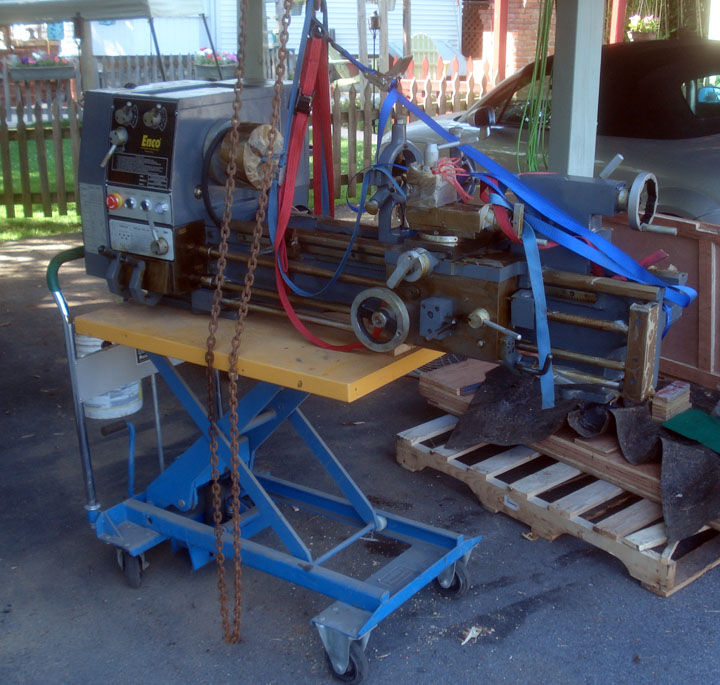

A heavy duty carriage was prepared to build the cabinet stands and chip tray on.

Welded and installed a hoist mount point to the overhead. Used a chain hoist to lift the lathe ....

To the point where I could get a borrowed lift table under it. I lifted with the table and hoist both. The lathe was over the capacity for each by a bit.

After the lift, I counted on the hoist to float the lathe while the carriage and cabinets were moved under it. The mounting holes were lined up with the lathe barely putting weight on the base. Everything was bolted into place.

Door jam and corner of the building was removed to make access

The lathe and carriage was positioned.

The room was rearragned to accept the machine. A 20 ton hydraulic press I made many years ago was displaced to the other end of this shop room. Note the small 8 by 18 bench lathe on the bench right.

The lathe was rolled into place. And now I'll wire it in, and set it up.

Gary

Edited 2 time(s). Last edit at 06/15/2010 01:39AM by barnespneumatic.

Welded and installed a hoist mount point to the overhead. Used a chain hoist to lift the lathe ....

To the point where I could get a borrowed lift table under it. I lifted with the table and hoist both. The lathe was over the capacity for each by a bit.

After the lift, I counted on the hoist to float the lathe while the carriage and cabinets were moved under it. The mounting holes were lined up with the lathe barely putting weight on the base. Everything was bolted into place.

Door jam and corner of the building was removed to make access

The lathe and carriage was positioned.

The room was rearragned to accept the machine. A 20 ton hydraulic press I made many years ago was displaced to the other end of this shop room. Note the small 8 by 18 bench lathe on the bench right.

The lathe was rolled into place. And now I'll wire it in, and set it up.

Gary

Edited 2 time(s). Last edit at 06/15/2010 01:39AM by barnespneumatic.

|

Re: Lathe Progress June 13, 2010 04:46PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: Lathe Progress June 13, 2010 06:21PM |

Registered: 15 years ago Posts: 966 |

|

Re: Lathe Progress June 14, 2010 04:24AM |

Registered: 15 years ago Posts: 780 |

|

Re: Lathe Progress June 14, 2010 04:31AM |

Registered: 15 years ago Posts: 633 |

Very nice GB. Funny how much RIGGING it takes just to move heavy objects. But man does the rigging make it so much easier.

But, i am gonna have to deduct some KUDO points that i gave to you because of that RUSTY chain fall. TISK TISK TISK mr GB. A new healthy chain fall is in order.

LOL...sorry but, my boss is sooooo anal about having our hoisting equipment inspected and replaced when necessary. If we lift one thing that is at the chain falls max capacity, he trashes it and buys us a new one. So yeah, i'm pretty spoiled when it comes to stuff like that.

But, i am gonna have to deduct some KUDO points that i gave to you because of that RUSTY chain fall. TISK TISK TISK mr GB. A new healthy chain fall is in order.

LOL...sorry but, my boss is sooooo anal about having our hoisting equipment inspected and replaced when necessary. If we lift one thing that is at the chain falls max capacity, he trashes it and buys us a new one. So yeah, i'm pretty spoiled when it comes to stuff like that.

|

Re: Lathe Progress June 14, 2010 03:09PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hi Cedric,

Yeah ... this isn't a Union Shop. And we don't do government contracts.

That was my father's chain fall. No ... I don't mean it's sacred or anything. Just yet another old rusty tool that got the job done. It probably came from some previous old guy's shop.

Yep ... Government contracts ... that's where the new cool tools are. And, working for somebody else ... that's the cushy job. My tools have to come out of my paper towel budget. hahah.

Gary

Yeah ... this isn't a Union Shop. And we don't do government contracts.

That was my father's chain fall. No ... I don't mean it's sacred or anything. Just yet another old rusty tool that got the job done. It probably came from some previous old guy's shop.

Yep ... Government contracts ... that's where the new cool tools are. And, working for somebody else ... that's the cushy job. My tools have to come out of my paper towel budget. hahah.

Gary

|

Re: Lathe Progress June 14, 2010 11:00PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Re: Lathe Progress June 15, 2010 01:38AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

The corner of the building is restored. Even corrected the rotted mess I found when I opened it up. 1894 junk just doesn't last ...

hahah

hahah

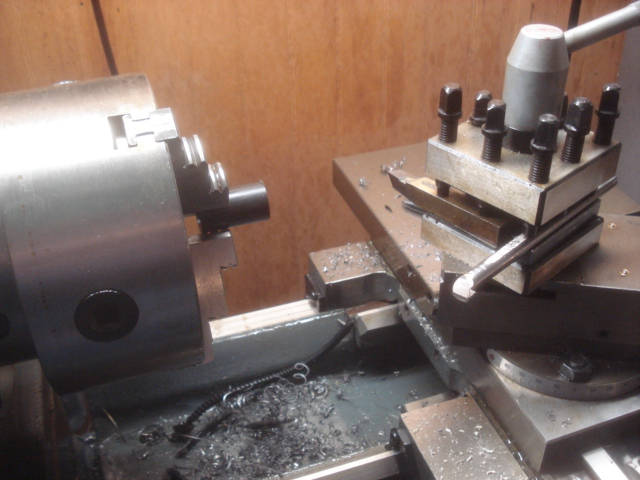

The lathe is installed. Wired in (thanks Kent for the good thought ... I found the wiring SNAFU). It's cleaned of cosmaline and wax paper wrap. It's been lubricated. The two oil sumps have been filled with oil. I even finally figured out the nine layers of safety settings before you can finally lite the thing up. My other lathe (Clausing ... might be from 1940 by the serial number) ... anyway ... you turn it "ON" and it's running. This one, you have to set a master switch to "ON" - which just lights a green light. Then, the feed lever must be in neutral. The kill button must be "Armed". The forward / reverse lever must be in neutral. You push the "Power Start" button, which just gives you an additional red light. And THEN ... THEN ... you can trigger a lever to start the headstock. Evidently lawyers have been discovered in China.

This has been quite a project. Just so I can work. I do have orders that will be more effecient with this lathe's capacity. I can think of three without even trying. Probably more. And I can develop additional. I worked on this at the fastest pace I was able, to meet the shop's needs without taking too much time from production. I hope it serves well for many years.

Gary

Edited 1 time(s). Last edit at 06/15/2010 01:47AM by barnespneumatic.

|

Re: Lathe Progress June 15, 2010 10:18AM |

|

Admin Registered: 15 years ago Posts: 665 |

|

Re: Lathe Progress June 15, 2010 05:16PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Re: Lathe Progress June 15, 2010 11:52PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

BTW

The lathe works great. I like it. Used it some today on work I could have done on the other one, but wanted to run it some. Worked very well. Some things I did on it, I could not have done on the others.

I also cast some special stuff today for a customer.

Also spent much of the day making trigger block parts for the Hagan Nitro. That's coming along well.

First thing this am, I decided to secure a shelf/stand near the new lathe ... and put a long dry wall screw thru a 110 volt line inside the wall. Lots of sparks and noise. And then I stripped that out, and replaced it. All in a day's fun.

Lots of sparks and noise. And then I stripped that out, and replaced it. All in a day's fun.

Coffee now, and one more cycle in the shop. The 8 pm until whenever shift.

Gary

The lathe works great. I like it. Used it some today on work I could have done on the other one, but wanted to run it some. Worked very well. Some things I did on it, I could not have done on the others.

I also cast some special stuff today for a customer.

Also spent much of the day making trigger block parts for the Hagan Nitro. That's coming along well.

First thing this am, I decided to secure a shelf/stand near the new lathe ... and put a long dry wall screw thru a 110 volt line inside the wall.

Lots of sparks and noise. And then I stripped that out, and replaced it. All in a day's fun.

Lots of sparks and noise. And then I stripped that out, and replaced it. All in a day's fun.

Coffee now, and one more cycle in the shop. The 8 pm until whenever shift.

Gary

|

Re: Lathe Progress June 15, 2010 01:52AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hey ... what's sah mattr? Youz ain't never heawd of RECYCLING?

Today's hand drying towels, becomes tomorrow's oil wiping towels. (Or ... they might be yet again ... hand wiping towels ... Usually though, for guests, I don't require more than three usages for hands before we move them along ...

Usually though, for guests, I don't require more than three usages for hands before we move them along ...

hehe

Gary

Today's hand drying towels, becomes tomorrow's oil wiping towels. (Or ... they might be yet again ... hand wiping towels ...

Usually though, for guests, I don't require more than three usages for hands before we move them along ...

Usually though, for guests, I don't require more than three usages for hands before we move them along ...

hehe

Gary

|

Re: Lathe Progress June 15, 2010 02:31AM |

|

Admin Registered: 15 years ago Posts: 2,400 |

Re: Lathe Progress FINAL PICS ADDED  June 15, 2010 02:34PM |

Registered: 15 years ago Posts: 184 |

Re: Lathe Progress FINAL PICS ADDED  June 15, 2010 05:10PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Keith,

So far, it has indeed proven magical. It expands to meet the need. I've set up for more unique operations in that small building, than could be imagined.

As you see in the pics, the building opened to admit the lathe, and then healed behind it. That's been done a few times. haha.

I have to be careful to keep a door open to the outside ...

Best,

Gary

So far, it has indeed proven magical. It expands to meet the need. I've set up for more unique operations in that small building, than could be imagined.

As you see in the pics, the building opened to admit the lathe, and then healed behind it. That's been done a few times. haha.

I have to be careful to keep a door open to the outside ...

Best,

Gary

Re: Lathe Progress FINAL PICS ADDED  June 16, 2010 02:21PM |

Registered: 15 years ago Posts: 294 |

Re: Lathe Progress FINAL PICS ADDED  June 16, 2010 02:29PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

|

Anonymous User

Re: Lathe Progress FINAL PICS ADDED  June 16, 2010 06:42PM |

Re: Lathe Progress FINAL PICS ADDED  June 16, 2010 06:56PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Joe,

The shop is fed from an underground trunk line from the house. Doesn't have to be large. As you know, it's just little ole me in there. Turn one thing off - turn the next one on.

Getting the lathe set up was just another example of one small step at a time. No serious grunting involved. I've avoided that.

Glad it's done. Wheeew.

Gary

The shop is fed from an underground trunk line from the house. Doesn't have to be large. As you know, it's just little ole me in there. Turn one thing off - turn the next one on.

Getting the lathe set up was just another example of one small step at a time. No serious grunting involved. I've avoided that.

Glad it's done. Wheeew.

Gary

Re: Lathe Progress FINAL PICS ADDED  June 18, 2010 07:35PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

I've been getting good use from the lathe. It works very well.

I've used it for some normal things so far ... and it does those better than the previous main lathe. I also have it jacked up so I don't have to bend over to use it, or to examine the work. Might seem odd to machinists that aren't 6'3" with a bad back ... but works for me.

Gary

I've used it for some normal things so far ... and it does those better than the previous main lathe. I also have it jacked up so I don't have to bend over to use it, or to examine the work. Might seem odd to machinists that aren't 6'3" with a bad back ... but works for me.

Gary

Re: Lathe Progress FINAL PICS ADDED  June 19, 2010 02:26PM |

Admin Registered: 15 years ago Posts: 1,489 |

Re: Lathe Progress FINAL PICS ADDED  June 19, 2010 04:56PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Lon,

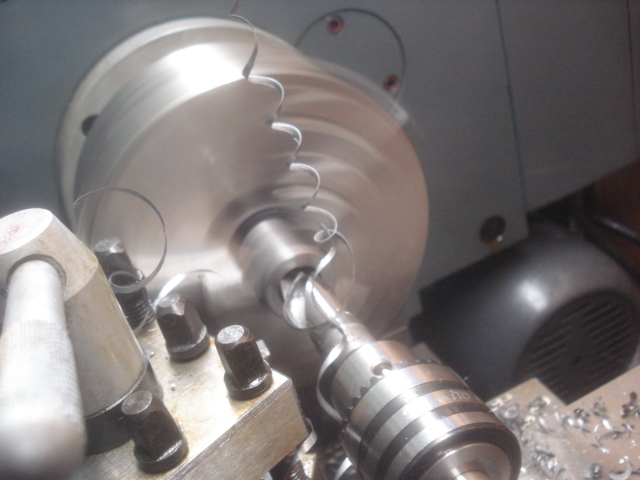

This is called a "Turret" tool post. It rotates and holds four different tools at a time. It adjusts and locks by hand. The other lathe, I fitted out with a dovetailed unit sold under the "Phase II" name from Enco. They work well. Each tool has to have it's carrier. Then, you pop then on and off and toss a lever which locks the dovetail. Works well. This is simplier and cheaper. The other is quicker to change tools that are adjusted. We'll see what I stick with on this.

Yes - it's against everything you've ever read about drilling to bedrock and bolting at lathe too the earth's core ... but I've always done this ... silly me. I don't want to have to hire a crane each time I need to shift the machine. The dolly is built like a truck to be solid. The lathe is built so ridgid that they recommend one strapping point to lift the machine. Right in front of the chuck. As you will note from my lift pics ... I used four straps and spread the load some. However; the bed is very solid.

So far - so good. The headstock needed 3+ quarts of oil to top it off. Must be a V-6 in there. haha.

Gary

This is called a "Turret" tool post. It rotates and holds four different tools at a time. It adjusts and locks by hand. The other lathe, I fitted out with a dovetailed unit sold under the "Phase II" name from Enco. They work well. Each tool has to have it's carrier. Then, you pop then on and off and toss a lever which locks the dovetail. Works well. This is simplier and cheaper. The other is quicker to change tools that are adjusted. We'll see what I stick with on this.

Yes - it's against everything you've ever read about drilling to bedrock and bolting at lathe too the earth's core ... but I've always done this ... silly me. I don't want to have to hire a crane each time I need to shift the machine. The dolly is built like a truck to be solid. The lathe is built so ridgid that they recommend one strapping point to lift the machine. Right in front of the chuck. As you will note from my lift pics ... I used four straps and spread the load some. However; the bed is very solid.

So far - so good. The headstock needed 3+ quarts of oil to top it off. Must be a V-6 in there. haha.

Gary

Re: Lathe Progress FINAL PICS ADDED  June 18, 2010 08:39PM |

Registered: 15 years ago Posts: 378 |

Re: Lathe Progress FINAL PICS ADDED  June 19, 2010 12:17AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Thanks Bill,

It's a nice lathe. Seems nice and true.

Karl,

The package shipped no problem. Fed Ex - Wed. I think it was.

Jerry,

Only the really cool machinists.

Hey ... last evening our Son and his twin grandsons - Bryce and Chance, and grandson Caden, all had dinner with us on the patio. Afterwards, I said I need to go back to work for awhile. Caden wanted to go into the shop with me to check things out. He walked thru, casting an eye here and there. Nothing seemed to spark a question or reaction. He kept following the twists and turns of the main isle, looking around. We got to the new lathe ... and I said, "there's Pop's new lathe" ... he didn't appear overly moved ... his looks from side to side increased ... and he said, "Did you make a mess in here?"

Gary

It's a nice lathe. Seems nice and true.

Karl,

The package shipped no problem. Fed Ex - Wed. I think it was.

Jerry,

Only the really cool machinists.

Hey ... last evening our Son and his twin grandsons - Bryce and Chance, and grandson Caden, all had dinner with us on the patio. Afterwards, I said I need to go back to work for awhile. Caden wanted to go into the shop with me to check things out. He walked thru, casting an eye here and there. Nothing seemed to spark a question or reaction. He kept following the twists and turns of the main isle, looking around. We got to the new lathe ... and I said, "there's Pop's new lathe" ... he didn't appear overly moved ... his looks from side to side increased ... and he said, "Did you make a mess in here?"

Gary

Re: Lathe Progress FINAL PICS ADDED  June 18, 2010 09:12PM |

Registered: 15 years ago Posts: 294 |

Re: Lathe Progress FINAL PICS ADDED  June 18, 2010 10:23PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

|

Anonymous User

Re: Lathe Progress FINAL PICS ADDED  June 20, 2010 03:51PM |

Re: Lathe Progress FINAL PICS ADDED  June 20, 2010 04:29PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Florida,

My shop is all manual. Manual readout. Simple tools. In that way, I can have more of the tools I really need.

All the bells and whistles are very nice, if you can afford to have a complete shop like that, and maintain it. I can't. It's all I can do to maintain the building and tooling I have.

Nice thing though, I can make jigs, fixtures, and tool bits, and use them for years. Rather than have employees breaking up three hundred dollar tool bits all day.

Gary

My shop is all manual. Manual readout. Simple tools. In that way, I can have more of the tools I really need.

All the bells and whistles are very nice, if you can afford to have a complete shop like that, and maintain it. I can't. It's all I can do to maintain the building and tooling I have.

Nice thing though, I can make jigs, fixtures, and tool bits, and use them for years. Rather than have employees breaking up three hundred dollar tool bits all day.

Gary

Re: Lathe Progress FINAL PICS ADDED  June 21, 2010 08:17PM |

Registered: 15 years ago Posts: 438 |

i really do think dr who built garys shed ,,, every time something is needed , well read found or wanted ,,, space becomes available , either that or its the only three story shed on the block ,

nice looking lathe , but its just like the rest , takes the man to drive it , and theres no one better for the job .

enjoy your new toy ,, oops tool

t

nice looking lathe , but its just like the rest , takes the man to drive it , and theres no one better for the job .

enjoy your new toy ,, oops tool

t

Re: Lathe Progress FINAL PICS ADDED  June 21, 2010 09:18PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Re: Lathe Progress FINAL PICS ADDED  June 27, 2010 05:40AM |

Registered: 15 years ago Posts: 2,524 |

Re: Lathe Progress FINAL PICS ADDED  June 27, 2010 02:39PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Re: Lathe Progress FINAL PICS ADDED  June 27, 2010 03:45PM |

|

Admin Registered: 15 years ago Posts: 2,400 |

Re: Lathe Progress FINAL PICS ADDED  June 27, 2010 03:49PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Re: Lathe Progress FINAL PICS ADDED  June 28, 2010 11:13PM |

Registered: 15 years ago Posts: 2,524 |

Re: Lathe Progress FINAL PICS ADDED  June 29, 2010 02:10AM |

|

Admin Registered: 15 years ago Posts: 2,400 |

Re: Lathe Progress FINAL PICS ADDED  June 29, 2010 02:29AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 12:37AM |

Registered: 15 years ago Posts: 2,524 |

Hey, you could just make the whole thing out of aluminum bronze if you want to! .gif)

That way, archaeologists ten thousand years from now can dig it out of the rubble of our civilization and say something like "Hmmm. a new set of O-rings and we're good to go. Hey check it out, it's still holding a charge..."

OK...perhaps I exaggerate just a bit...

.gif)

That way, archaeologists ten thousand years from now can dig it out of the rubble of our civilization and say something like "Hmmm. a new set of O-rings and we're good to go. Hey check it out, it's still holding a charge..."

OK...perhaps I exaggerate just a bit...

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 01:17AM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Nah ... what I fear is that ten thousand years from now ... archaeologists will find a crate, under a bed, with the screws still in the top of it. Note proudly proclaiming that the airgun inside is in "unfired condition".

"Use 'em up first ... then hang 'em on the wall". You don't need the cryptonite crystal trigger bearings ....

Gary

"Use 'em up first ... then hang 'em on the wall". You don't need the cryptonite crystal trigger bearings ....

Gary

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 06:10AM |

Registered: 15 years ago Posts: 2,524 |

WHAT?!? Shoot an airgun?!? And ruin it's collectors value?

I won't own something too pretty or valuable to shoot. If it's so rare that it'd be unethical or wrong to actually USE it, it belongs in a museum, not a personal collection. Some of my rifles actually have (gasp)...rusty spots! Actual wear and tear, to think...the horror...

On the other hand, where I live it's not uncommon to find cars driving around that actually have live moss growing in the holes where the rusted out spots collect road dirt, so...the weather around here MAY have something to do with it. That, and the fact that I never did get all the residue from that corrosive Berdan primed Chinese ammo out of the flash supressor on my AK.

I won't own something too pretty or valuable to shoot. If it's so rare that it'd be unethical or wrong to actually USE it, it belongs in a museum, not a personal collection. Some of my rifles actually have (gasp)...rusty spots! Actual wear and tear, to think...the horror...

On the other hand, where I live it's not uncommon to find cars driving around that actually have live moss growing in the holes where the rusted out spots collect road dirt, so...the weather around here MAY have something to do with it. That, and the fact that I never did get all the residue from that corrosive Berdan primed Chinese ammo out of the flash supressor on my AK.

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 03:02PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Hello Sean,

See, there's the confusion. Whenever you mention the "weather" your rifle will be subject to, you use as an illustration ... the rusted out rocker panel of a car on Alaskan roads.

I sort of figured you'd take a bit more care than that. Since it's been ordered that the smooth bore 62 barrel will be stainless. The reservoir/frame will be stainless, and everything else will be billet aluminum .... I've never understood the concern that the thing is going to rust into a solid lump of corrosion, overnight.

Since it's been ordered that the smooth bore 62 barrel will be stainless. The reservoir/frame will be stainless, and everything else will be billet aluminum .... I've never understood the concern that the thing is going to rust into a solid lump of corrosion, overnight.

I'd humbly suggest, that you move your rifle rack from under the car - to behind the seat.

Gary

See, there's the confusion. Whenever you mention the "weather" your rifle will be subject to, you use as an illustration ... the rusted out rocker panel of a car on Alaskan roads.

I sort of figured you'd take a bit more care than that.

Since it's been ordered that the smooth bore 62 barrel will be stainless. The reservoir/frame will be stainless, and everything else will be billet aluminum .... I've never understood the concern that the thing is going to rust into a solid lump of corrosion, overnight.

Since it's been ordered that the smooth bore 62 barrel will be stainless. The reservoir/frame will be stainless, and everything else will be billet aluminum .... I've never understood the concern that the thing is going to rust into a solid lump of corrosion, overnight.

I'd humbly suggest, that you move your rifle rack from under the car - to behind the seat.

Gary

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 04:19PM |

Registered: 15 years ago Posts: 2,524 |

What? You're not supposed to use these things to hold up the mudflaps on the dually? Whoda thunk?!?

Actually, it's probably a lot like your Gulf Coast customers (except a lot more snow and grizzly bears ). You don't actually have to get rained on actively for the rust to start, you just have to touch a blued gun and put it away without taking precautions for the rust to start. When the humidity levels never get below the high double digits, the moisture is always there...waiting...If you should happen to take a rifle on a hunting trip involving a boat, add in the everpresent salt spray and the even higher humidity/condensation that you get from living, breathing, and cooking in a refrigerated aluminum box. That's assuming that you didn't actually drop it in the ocean or a stream at some point, which is not a given when you're trudging through a temperate rainforest. And then there's the climbing in and out of zodiacs and skiffs, perhaps throw in transportation on an ATV or a snowmachine...you get the picture. Alaska is one of the places where stainless steel and synthetic stocks were made to go together. The one thing that you basically NEVER do on an Alaskan hunt is drive there in a nice, warm, dry truck.

). You don't actually have to get rained on actively for the rust to start, you just have to touch a blued gun and put it away without taking precautions for the rust to start. When the humidity levels never get below the high double digits, the moisture is always there...waiting...If you should happen to take a rifle on a hunting trip involving a boat, add in the everpresent salt spray and the even higher humidity/condensation that you get from living, breathing, and cooking in a refrigerated aluminum box. That's assuming that you didn't actually drop it in the ocean or a stream at some point, which is not a given when you're trudging through a temperate rainforest. And then there's the climbing in and out of zodiacs and skiffs, perhaps throw in transportation on an ATV or a snowmachine...you get the picture. Alaska is one of the places where stainless steel and synthetic stocks were made to go together. The one thing that you basically NEVER do on an Alaskan hunt is drive there in a nice, warm, dry truck.  Unless you live in Los Anchorage, in which case you're driving to the airport so you can fly to where the real Alaska starts.

Unless you live in Los Anchorage, in which case you're driving to the airport so you can fly to where the real Alaska starts.

The irony is that the best (and certainly the easiest) place to see moose in Alaska is probably in Anchorage...go figure. The combination of numerous large, wooded parks, plentiful (and tasty to moose) urban landscaping plantings, ease of winter access due to plowed roads, trails, and paths, comparitive scarcity of wolfs and bears, and the last 30 years of no hunting have led to a disproportionate number of moose living in Alaska's largest city. They experimented with an archery-only hunt a couple years ago, I'm not sure how that turned out. They tried an "urban archery hunt" for moose in the Anchorage area back in the 80's, but the bad publicity of seeing a couple of moose running around with arrows in their flanks and shoulders put an end to that for political reasons. I hope that the current crop of urban archery hunters do a better job, as the current default method of pruning down the moose population is via the "front bumper" method, which is hard on the drivers.

Actually, it's probably a lot like your Gulf Coast customers (except a lot more snow and grizzly bears

). You don't actually have to get rained on actively for the rust to start, you just have to touch a blued gun and put it away without taking precautions for the rust to start. When the humidity levels never get below the high double digits, the moisture is always there...waiting...If you should happen to take a rifle on a hunting trip involving a boat, add in the everpresent salt spray and the even higher humidity/condensation that you get from living, breathing, and cooking in a refrigerated aluminum box. That's assuming that you didn't actually drop it in the ocean or a stream at some point, which is not a given when you're trudging through a temperate rainforest. And then there's the climbing in and out of zodiacs and skiffs, perhaps throw in transportation on an ATV or a snowmachine...you get the picture. Alaska is one of the places where stainless steel and synthetic stocks were made to go together. The one thing that you basically NEVER do on an Alaskan hunt is drive there in a nice, warm, dry truck.

). You don't actually have to get rained on actively for the rust to start, you just have to touch a blued gun and put it away without taking precautions for the rust to start. When the humidity levels never get below the high double digits, the moisture is always there...waiting...If you should happen to take a rifle on a hunting trip involving a boat, add in the everpresent salt spray and the even higher humidity/condensation that you get from living, breathing, and cooking in a refrigerated aluminum box. That's assuming that you didn't actually drop it in the ocean or a stream at some point, which is not a given when you're trudging through a temperate rainforest. And then there's the climbing in and out of zodiacs and skiffs, perhaps throw in transportation on an ATV or a snowmachine...you get the picture. Alaska is one of the places where stainless steel and synthetic stocks were made to go together. The one thing that you basically NEVER do on an Alaskan hunt is drive there in a nice, warm, dry truck.  Unless you live in Los Anchorage, in which case you're driving to the airport so you can fly to where the real Alaska starts.

Unless you live in Los Anchorage, in which case you're driving to the airport so you can fly to where the real Alaska starts.

The irony is that the best (and certainly the easiest) place to see moose in Alaska is probably in Anchorage...go figure. The combination of numerous large, wooded parks, plentiful (and tasty to moose) urban landscaping plantings, ease of winter access due to plowed roads, trails, and paths, comparitive scarcity of wolfs and bears, and the last 30 years of no hunting have led to a disproportionate number of moose living in Alaska's largest city. They experimented with an archery-only hunt a couple years ago, I'm not sure how that turned out. They tried an "urban archery hunt" for moose in the Anchorage area back in the 80's, but the bad publicity of seeing a couple of moose running around with arrows in their flanks and shoulders put an end to that for political reasons. I hope that the current crop of urban archery hunters do a better job, as the current default method of pruning down the moose population is via the "front bumper" method, which is hard on the drivers.

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 06:36PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Re: Lathe Progress FINAL PICS ADDED  June 30, 2010 08:23PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

That being said, there's no way that this project is designed to be something that can be submerged in saltwater, and carried openly on a snowmobile expedition without effect. No airtight trigger block - no sealed internal hammer subset. I certainly hope that that is not the expectation.

There are dozens of small springs, screws, trigger block levers, and firing components ... that will not be made of stainless steel. Stainless tool steel components are not the equal of carbon tool steel components. Springs aren't as good. Edges don't hold as well. Screws are not as strong. The stainless was offered for it's cosmetic nature, and maintenance ease. It was never sold as a thru and thru indestructable and eternal option. (Would have cost a bit more for that ....gif)

So - hope we're on the same page.

Gary

There are dozens of small springs, screws, trigger block levers, and firing components ... that will not be made of stainless steel. Stainless tool steel components are not the equal of carbon tool steel components. Springs aren't as good. Edges don't hold as well. Screws are not as strong. The stainless was offered for it's cosmetic nature, and maintenance ease. It was never sold as a thru and thru indestructable and eternal option. (Would have cost a bit more for that ...

.gif)

So - hope we're on the same page.

Gary

Re: Lathe Progress FINAL PICS ADDED  July 03, 2010 10:20AM |

Registered: 15 years ago Posts: 2,524 |

Yes, very much on the same page. Idiot proof and indestructable are NOT blocks that can be checked off on the options menu, same with "completely maintenance free" and "totally, completely rust-proof".

Contrary to what might be assumed from the above, I do actually own both a water-resistant gun case AND can of light gun oil and I have been known to use them from time to time.

And yes, I am aware that your rifles are not designed for underwater use, despite how cool that might sound on the internet. Or did I miss the "floating spear-gun option block" as well?

Contrary to what might be assumed from the above, I do actually own both a water-resistant gun case AND can of light gun oil and I have been known to use them from time to time.

And yes, I am aware that your rifles are not designed for underwater use, despite how cool that might sound on the internet. Or did I miss the "floating spear-gun option block" as well?

Re: Lathe Progress FINAL PICS ADDED  July 03, 2010 05:39PM |

|

Admin Registered: 15 years ago Posts: 14,038 |

Sorry, only registered users may post in this forum.

Online Users

Guests:

16

Record Number of Users:

4

on March 10, 2022

Record Number of Guests:

234

on February 21, 2021

I've not mentioned it but one of the posted shop pictures shows just how tight the paper towel budget is!

I've not mentioned it but one of the posted shop pictures shows just how tight the paper towel budget is!

... and I have that truck load of stainless machine screws coming too ...

... and I have that truck load of stainless machine screws coming too ...